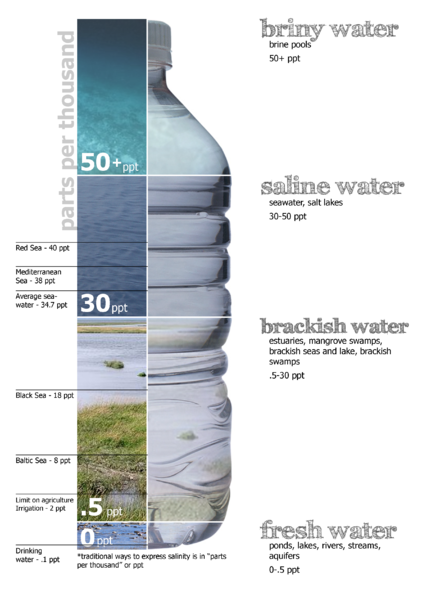

<div class="text-justify">  <center><sup>[Cover image using as image the well intervention ship Sarah. Source](https://en.wikipedia.org/wiki/File:Well_intervention_vessel_Sarah.JPG)</sup></center> In this opportunity I want to explain to you the generalities in the use and application of the fluids that are used at the moment of the culmination of the drilling of a well and also when activities of repair of the same one are made. Due to the diversity in the use of the fluids used in the activities of completion and repair of oil wells it is necessary to explain what type of fluid can be used depending on the stage in which it is going to be used, these fluids differ in many characteristics to drilling fluids and are used for the simple fact of taking care of the producing formation especially when repair activities are going to be carried out, Whether you need to control pressures at the bottom of the well or when you need to perform well cleanup activities, to give you an idea you can use everything from fluids such as brines that provide hydrostatic pressure when performing well repair work, to using fluids with various chemical additives to clean up wells that may have sandblasting problems in petroleum production.  <center><sup>[Image Source](https://en.wikipedia.org/wiki/File:DiamondRig-SuperFoam.jpg)</sup></center> The main use that these types of fluids have, for example, is that during well completion activities the future production capacity of the producing reservoir can be minimized, that is why when they are being lowered to the bottom of the well the completion tools and equipment try to use light fluids such as diesel that does not have a high density that can plug the pores of the producing reservoir formation. There are many jobs that are done in an oil well where the uses and applications of these completion and repair fluids are of paramount importance, among which are the following: - Forced cementing. - Fracturing. - Acidification. - Stimulation. - Plugging. - Well cleaning. - Packing fluids. - Completion and circulation fluids, among others. Fluids that can meet the minimum requirements for these jobs include: gaseous fluids, oil, brine water, sludge or other chemical solutions used during normal intervention activities. It should be noted, as I said before, that the diversity of these fluids is due to the fact that all well completion and repair works do not contemplate the same characteristics and requirements, therefore for a given activity a particular type of fluid must be used. An example of this may be that you need to use a gaseous fluid to perform a stimulation work in the well because they have low density, but suddenly this same gaseous fluid can not meet the same requirements to perform a cleanup work of the well, where most likely you have to use a fluid that is compatible with the lithologic formation in the bottom of the well and at the same time can have a favorable hydraulic in the effective cleaning of the well. The main objective in the development of this article is to enable the reader to quickly grasp the type of fluid and its characteristics that should be used in the completion and repair of a well. We may think that drilling fluids can be used in certain special activities, but this is not really the case, since drilling fluids possess certain characteristics in their properties that make their use inappropriate. Knowing the characteristics of the fluids most commonly used in completion and repair activities of wells gives us an idea of how to select the most appropriate fluid for the activity to be executed, the importance of knowing the characteristics of some completion and repair fluids depends on this. <center></center> <center><sup>[Image Source](https://en.wikipedia.org/wiki/File:Workover_Rig_doing_a_Snub_Job.JPG)</sup></center> ### ***Characteristics required for oil well repair and completion fluids*** <p> The density is a very important physical property to evaluate and take into account when selecting the fluid and depending on the work to be done in the well. For example, if you are going to rehabilitate a well and its re-entry implies having to control the pressures at the bottom of the well, the fluid to be used must be dense enough to control the pressures of the well, and thus prevent an emergence that would result in the unwanted blowout, but at the same time it is not so dense that an invasion of the repair and completion fluid into the producing reservoir occurs, this means that the density is recommended to be in the balance, this means that the density should provide a hydrostatic pressure a little above the reservoir pressure. It is also important to include within the stakes characteristics of the completion and workover fluids that can meet the cost optimization process, ie the fluid chosen must be sufficiently effective in relation to their cost, remember that if you are going to repair a well and the use of a repair fluid is highly expensive suddenly does not make viable the need to get to repair the well, as everyone knows the optimization is a factor that determines the ability to make a design with guidelines that are valid within the engineering in this type of work. From the experience of some well rehabilitation works, I can tell you that not always choosing expensive fluids is the best option, for this it is necessary to use fluids that can be economically profitable and that in turn can serve to prevent damage in sensitive formations. It is necessary to understand well the operation to be executed based on the properties of the fluid, since you can have a good choice that provides a less expensive fluid than others commonly used, which usually could cause little or no damage to the formation, that is why experience is very valuable in these cases. In this process of cost optimization in the use of completion and workover fluids I want to tell my work experiences as a result of this optimization topic so that my reader friends and supporters can draw their own conclusions: ***When I was in charge as PDVSA's team leader in the Las Palmas field in the municipality of Jesús María Semprum in the State of Zulia - Venezuela, I was in charge of the rehabilitation operations of the Basil-09 drill, specifically in the Bx-07 well where a change of electro-submersible pumping was required. The rehabilitation program required that brine (water + industrial salt) be used as a control fluid in the well, but checking the reservoir pressure in the well I was able to verify that the well could be controlled simply with water, Knowing that the density of water is 8.33 lbs/gal, I made the corresponding calculations and notified my superiors, they found that the work could be done using only industrial water as a control fluid in this rehabilitation work. With this selection, they were able to lower the cost of salt, which was quite considerable, and at the same time, they were going to minimize the damage to the formation, since only with water could they obtain a lower density, reducing possible damage to the formation.*** <center></center> <center><sup>[Image Source](https://en.wikipedia.org/wiki/File:Water_salinity_diagram.png)</sup></center> If the workover in the well involves using a high-density fluid to control bottom pressures, a fluid high in solids is likely to be used to help increase density, but this in turn can be a future problem as those solid parts of the fluid can cover the porous spaces of the formation , reducing the permeability of training and jeopardizing the productivity of the producing site in the future. All this makes us think about the idea of needing a reduction of those solids without losing that ability to generate a high fluid density to control the pressures at the bottom of the well. A very important feature to take into account when selecting the well repair fluid is that it can maintain stability, since it is very important that when the fluid is going to stay long periods of time inside the well it has in its preparation the properties necessary to withstand the conditions at the bottom of the well, when we talk about stability I mean that the fluid can maintain its most important properties even though it is subjected to high temperatures. If the stability in its most important properties is lost, irreparable damage to the well can occur, resulting in additional costs in the recovery of tools and pipes stuck and left in the well, thus being able to raise the chances of abandonment and loss of the well. Having the ability to maintain its most important properties at normal values will help minimize costs for tool losses in the well and even possible well loss. ### ***Functions of well workover fluids*** <p> Termination and repair fluid functions are standard. The fluids used in these activities are necessary for the success of these works. Among the various functions that these fluids must perform, they must allow their use not to damage production training and be non-hazardous to: equipment, employees, personnel and environment, so it is of great importance that termination and repair fluids are properly applied and controlled. Termination and repair fluids range from low density fluids (gaseous fluids) to high-density fluids (liquid fluids). Its basic functions are set out below: [1] There must be this ability on the part of the fluid to allow the transport of certain tools from the surface to the bottom of the well, this is for example because if in the repair activity to be performed to the well contemplates that pipe has to be lowered or some tool time, the fluid to be used in this repair must allow the transport of any tool or materials. Among the most commonly used materials to be introduced into the well by means of the termination and repair fluid are: acid, cement, gelatinized pills, plastic, gravel, fracture sand, sealants among others. In conclusion, the selected fluid must fulfill the function of being able to transport unwanted materials out of the well, and to be able to transport certain desired materials within the well, there are many negative consequences if the selected fluid fails to transport unwanted fluids out of the well, among which we can name: jam of the pipe pan, increase in torque and drag , loss of circulation, obstruction of the formation and excessive wear of the equipment. [2] The fluid must have the ability to keep materials in suspension when fluid circulation stops. When repair and rehabilitation activities are carried out it is necessary that certain solid materials that can be found in the well are suspended when the circulation of the fluid is stopped, since in the event that solid materials return to the bottom of the well make it possible to stop repair activities in the well. If the selected fluid has a good gel strength property, then it will have a good suspension capacity when circulation is ted. It is thanks to this gelatinous form of fluid that the solids and cuts found in the well are reluctant to return to the bottom of the well. However, during repair operations most of the chip is removed from the well by a method called reverse circulation carried out at high speeds, thus reducing the operating time. It is very important that we analyze other possibilities of implementing other types of fluids that may not have such a high gel property, if the well has a lot of garbage in the background a high gel property may be needed, but this condition can lead to certain operational problems such as compression and pistoning pressures, thus causing a softness in the well and a possible rise of unwanted fluids to the well. [3] All the functions of these types of fluids are important but without a doubt that the function that I consider most important is to control the pressures at the bottom of the well, for this the fluid used must allow an increase in density at the time it is merited, for this we must keep in mind that when we carry out a repair activity we are exposed to high training pressures. It is necessary that we do not trust each other by carrying out these activities rehabilitation and repair of wells since on some occasions the activity can be carried out in a well that shows at first low training pressures, a circumstance that can suddenly change at high training pressures, so it is advisable to have in application a fluid that can control these training pressures. It needs to be balanced and in some cases over-balancing the training pressure to prevent the flow of unwanted fluids to the well. The termination and/or repair fluid possess the ability that they can be adjusted or densified at any time and in this way obtain that condition of balance between the pressures, always taking into account that the hydrostatic pressure of the selected fluid must not exceed the fracture pressure of the formation so that no losses and damage to the formation occur. [4] The selected fluid should be non-harmful to people and the environment, from experience in various well completing work and other improvement work to increase productivity, I have had the opportunity to monitor activities with the use of fluids that are often harmful to staff and the environment, for example among these fluids are: acids, some hydrochlorides among other chemicals that can cause high severity burns. From the above it is recommended to use personal protective equipment for when handling with these chemicals, to prevent contamination of these agents with the environment, from experience what I can recommend is a high supervision in operations to avoid by all means some type of spill where you can have contact of these chemical agents with some component of the environment. Science and technology need to make future contributions in the event that the oil industry remains active in being able to provide formulations in the preparation of many of these fluids to be compatible with the lithological formations of the subsurface, so that aquifers are not contaminated and above all so that the personnel exposed in the preparation of these fluids are not in danger of exposing many of these chemicals with that these fluids are prepared. ### ***Conclusion and contributions to oil engineering and the oil industry*** <p> Through this post I am providing any student studying oil engineering with the opportunity to select some fluid that can meet the operational requirements within the repair and completion activities of an oil well, the other important thing is that the selection criteria that are provided here in this post allow the oil engineering student to form their own criteria and analyze the importance in the diversity of these fluids. The work experiences provided here can serve as a stimulus for students to compare theories about well completion and completion fluids with the reality of the labor field in the construction of an oil well. In relation to the oil industry through this post you can know the various functions that can be fulfilled by many of these fluids in relation to the rehabilitation and completement of wells, taking into account the requirements that each specific job needs. Analyzing the most relevant aspects of this publication with regard to well repair and rehabilitation fluids I must say that these have many characteristics identical to drilling fluids, i.e. in both well drilling activities and well rehabilitation fluids the fluid to be used must possess the ability to control pressures at the bottom of the well , thus avoiding a burst of fluids on the surface. With regard to the functions performed by these fluids I can conclude that the functions of well repair and rehabilitation fluids have a lot of similarity to drilling fluids, however the difference is that repair fluids must have the physical characteristics necessary not to cover the pores of the formation of the producing deposit and this contribute to the productivity of the producing deposit. ### ***Recommended and consulted references*** <p> [Rubber Linings for Oilfield Equipment](https://www.sciencedirect.com/topics/engineering/completion-fluid) [Formation damage from completion workover fluids](https://petrowiki.org/Formation_damage_from_completion_workover_fluids) [Completion Fluids Design Criteria and Current Technology Weaknesses](https://www.onepetro.org/conference-paper/SPE-19434-MS) </div>

| author | carlos84 | ||||||

|---|---|---|---|---|---|---|---|

| permlink | how-petroleum-well-completion-and-workover-fluids--1600296592 | ||||||

| category | hive-196387 | ||||||

| json_metadata | {"tags":["hive-196387","ocd","curangel","engineering","posh","palnet","neoxian","creativecoin","stem"],"app":"stemsocial"} | ||||||

| created | 2020-09-16 22:49:54 | ||||||

| last_update | 2020-09-17 01:40:18 | ||||||

| depth | 0 | ||||||

| children | 3 | ||||||

| last_payout | 2020-09-23 22:49:54 | ||||||

| cashout_time | 1969-12-31 23:59:59 | ||||||

| total_payout_value | 8.959 HBD | ||||||

| curator_payout_value | 9.038 HBD | ||||||

| pending_payout_value | 0.000 HBD | ||||||

| promoted | 0.000 HBD | ||||||

| body_length | 16,849 | ||||||

| author_reputation | 353,218,698,404,153 | ||||||

| root_title | "How Petroleum Well Completion and Workover Fluids are Used" | ||||||

| beneficiaries |

| ||||||

| max_accepted_payout | 1,000,000.000 HBD | ||||||

| percent_hbd | 10,000 | ||||||

| post_id | 99,665,952 | ||||||

| net_rshares | 64,307,245,691,332 | ||||||

| author_curate_reward | "" |

| voter | weight | wgt% | rshares | pct | time |

|---|---|---|---|---|---|

| tombstone | 0 | 67,522,318,983 | 3.15% | ||

| tuck-fheman | 0 | 583,122,861 | 2.6% | ||

| drifter1 | 0 | 919,121,578 | 2.6% | ||

| chris4210 | 0 | 16,245,842,357 | 2.6% | ||

| kevinwong | 0 | 1,467,208,481,527 | 17.5% | ||

| scalextrix | 0 | 1,190,683,342 | 2.6% | ||

| justtryme90 | 0 | 1,615,999,141 | 40% | ||

| eric-boucher | 0 | 10,701,428,299 | 2.6% | ||

| anwenbaumeister | 0 | 235,881,116 | 5.2% | ||

| mammasitta | 0 | 25,047,238,383 | 3.5% | ||

| skapaneas | 0 | 848,265,868 | 12% | ||

| gerber | 0 | 122,191,297,680 | 2% | ||

| roelandp | 0 | 1,119,169,017,747 | 20% | ||

| ezzy | 0 | 142,261,426,247 | 2% | ||

| matt-a | 0 | 4,498,927,147 | 10.14% | ||

| redpalestino | 0 | 1,115,159,742,074 | 25% | ||

| onthewayout | 0 | 571,423,879,568 | 100% | ||

| mrwang | 0 | 4,610,004,296 | 8.75% | ||

| diana.catherine | 0 | 576,673,925 | 2.6% | ||

| arcange | 0 | 62,574,230,827 | 2% | ||

| exyle | 0 | 124,544,248,561 | 2% | ||

| arconite | 0 | 6,203,950,014 | 8.75% | ||

| raphaelle | 0 | 1,795,144,850 | 2% | ||

| djennyfloro | 0 | 1,309,633,244 | 10% | ||

| randomblock1 | 0 | 693,321,160 | 5.2% | ||

| kpine | 0 | 2,010,880,447,597 | 10% | ||

| rmach | 0 | 13,838,829,964 | 20% | ||

| sc-steemit | 0 | 1,231,548,533 | 2.6% | ||

| lemouth | 0 | 540,325,790,805 | 30% | ||

| netaterra | 0 | 38,632,358,130 | 1.8% | ||

| someguy123 | 0 | 65,609,189,631 | 2% | ||

| notconvinced | 0 | 21,800,725,710 | 40% | ||

| charlie777pt | 0 | 2,026,140,196 | 5% | ||

| alaqrab | 0 | 3,053,484,076 | 2.6% | ||

| lamouthe | 0 | 3,362,655,191 | 40% | ||

| uwelang | 0 | 26,631,769,343 | 2.6% | ||

| holoz0r | 0 | 2,034,487,484 | 7.8% | ||

| tfeldman | 0 | 4,624,173,060 | 2.6% | ||

| seckorama | 0 | 1,288,870,494 | 1.56% | ||

| edgarsart | 0 | 1,004,031,721 | 1.3% | ||

| mcsvi | 0 | 120,373,546,148 | 50% | ||

| lk666 | 0 | 2,405,671,292 | 2.6% | ||

| cnfund | 0 | 2,015,162,216 | 2.6% | ||

| michelle.gent | 0 | 1,029,000,816 | 1.04% | ||

| steemyoda | 0 | 683,686,211 | 28% | ||

| curie | 0 | 932,548,189,094 | 5.2% | ||

| modernzorker | 0 | 2,528,586,496 | 3.64% | ||

| reddust | 0 | 7,865,207,667 | 1.56% | ||

| techslut | 0 | 90,563,921,931 | 16% | ||

| hendrikdegrote | 0 | 68,362,111,850 | 5.2% | ||

| steemstem | 0 | 4,250,730,010,744 | 40% | ||

| tristancarax | 0 | 5,820,106,249 | 2.6% | ||

| zorg67 | 0 | 656,887,578 | 100% | ||

| oleg326756 | 0 | 1,408,803,430 | 8.75% | ||

| edb | 0 | 615,419,943 | 0.52% | ||

| yadamaniart | 0 | 1,718,690,897 | 2.6% | ||

| apsu | 0 | 3,246,167,536 | 1.82% | ||

| valth | 0 | 5,164,384,121 | 20% | ||

| saleg25 | 0 | 1,979,539,093 | 14.5% | ||

| lastminuteman | 0 | 1,158,738,687 | 1.82% | ||

| driptorchpress | 0 | 2,391,600,331 | 2.6% | ||

| dna-replication | 0 | 11,589,031,040 | 40% | ||

| steemitboard | 0 | 3,787,321,667 | 2% | ||

| ambyr00 | 0 | 4,245,951,960 | 0.78% | ||

| gmedley | 0 | 1,099,099,551 | 2.6% | ||

| nasgu | 0 | 5,792,447,427 | 5.2% | ||

| titianus | 0 | 676,700,902 | 14.5% | ||

| dhimmel | 0 | 648,912,373,098 | 10% | ||

| damla | 0 | 1,425,359,566 | 2.6% | ||

| detlev | 0 | 222,709,151,670 | 17.5% | ||

| chasmic-cosm | 0 | 642,637,416 | 2.6% | ||

| miniature-tiger | 0 | 91,138,367,939 | 50% | ||

| ma1neevent | 0 | 4,338,623,377 | 15% | ||

| sokha | 0 | 1,634,079,824 | 12.5% | ||

| bloom | 0 | 205,551,913,156 | 40% | ||

| dune69 | 0 | 13,829,979,188 | 2% | ||

| federacion45 | 0 | 5,640,431,410 | 2.6% | ||

| kingkinslow | 0 | 1,126,569,100 | 17.5% | ||

| iansart | 0 | 8,557,641,793 | 2.6% | ||

| mobbs | 0 | 71,768,489,490 | 20% | ||

| jagged | 0 | 941,492,311 | 1.04% | ||

| activate.alpha | 0 | 44,802,084,827 | 5% | ||

| roomservice | 0 | 469,781,083,510 | 10.5% | ||

| farizal | 0 | 8,374,358,893 | 24% | ||

| mys | 0 | 96,152,885 | 0.2% | ||

| ironshield | 0 | 1,737,912,711 | 2.6% | ||

| sustainablyyours | 0 | 2,172,563,763 | 2.6% | ||

| erick1 | 0 | 659,959,953 | 2.6% | ||

| helo | 0 | 35,426,960,257 | 20% | ||

| freetissues | 0 | 1,027,607,439 | 2.6% | ||

| samminator | 0 | 22,665,713,284 | 20% | ||

| arrliinn | 0 | 12,892,545,373 | 17.5% | ||

| zerotoone | 0 | 1,037,600,685 | 2.6% | ||

| locikll | 0 | 2,149,454,732 | 10.4% | ||

| kalinka | 0 | 1,001,191,086 | 2.6% | ||

| mahdiyari | 0 | 585,696,839,665 | 100% | ||

| lorenzor | 0 | 6,976,860,777 | 50% | ||

| firstamendment | 0 | 50,327,280,470 | 50% | ||

| aboutyourbiz | 0 | 975,807,403 | 5.2% | ||

| alexander.alexis | 0 | 23,964,137,726 | 40% | ||

| ew-and-patterns | 0 | 175,459,556,051 | 9% | ||

| hhayweaver | 0 | 1,879,153,176 | 2.6% | ||

| gunthertopp | 0 | 19,427,774,980 | 0.41% | ||

| pisolutionsmru | 0 | 712,081,708 | 2.6% | ||

| binkyprod | 0 | 1,876,952,994 | 2.6% | ||

| ludmila.kyriakou | 0 | 2,809,974,169 | 12% | ||

| flatman | 0 | 3,880,149,929 | 5.2% | ||

| samest | 0 | 1,371,686,316 | 50% | ||

| dante31 | 0 | 4,248,026,355 | 17.5% | ||

| allcapsonezero | 0 | 584,342,795 | 2.6% | ||

| wandergirl | 0 | 2,641,801,007 | 17.5% | ||

| minnowbooster | 0 | 1,847,205,769,944 | 20% | ||

| andre-verbrick | 0 | 197,203,995,982 | 100% | ||

| howo | 0 | 1,569,458,839,684 | 35% | ||

| tsoldovieri | 0 | 4,057,017,309 | 20% | ||

| shitsignals | 0 | 822,215,012 | 2% | ||

| neumannsalva | 0 | 2,078,447,850 | 2.6% | ||

| stayoutoftherz | 0 | 93,213,502,425 | 2.6% | ||

| abigail-dantes | 0 | 53,342,178,762 | 40% | ||

| ocd | 0 | 3,527,833,145,332 | 35% | ||

| carlos-fernando | 0 | 4,963,987,671 | 40% | ||

| tykee | 0 | 5,434,592,737 | 50% | ||

| sciencevienna | 0 | 16,848,584,446 | 22% | ||

| investingpennies | 0 | 14,467,416,897 | 5.2% | ||

| redrica | 0 | 18,850,573,156 | 15.95% | ||

| appleskie | 0 | 1,078,709,861 | 3.64% | ||

| iamphysical | 0 | 6,571,433,236 | 90% | ||

| emekasegun | 0 | 721,527,702 | 2.6% | ||

| felixrodriguez | 0 | 1,153,849,832 | 20% | ||

| chrisdavidphoto | 0 | 858,384,216 | 1.56% | ||

| betterthanhome | 0 | 9,107,297,293 | 2.6% | ||

| revo | 0 | 21,113,170,997 | 5.2% | ||

| azulear | 0 | 4,079,466,390 | 100% | ||

| djlethalskillz | 0 | 3,604,691,130 | 10% | ||

| stickchumpion | 0 | 972,986,420 | 2.6% | ||

| noloafing | 0 | 4,678,822,733 | 10% | ||

| thelordsharvest | 0 | 8,794,958,809 | 5.2% | ||

| kimzwarch | 0 | 10,073,202,012 | 4% | ||

| olusolaemmanuel | 0 | 837,876,666 | 3.64% | ||

| massivevibration | 0 | 9,596,253,898 | 5% | ||

| nurhayati | 0 | 773,563,258 | 17.5% | ||

| bradfordtennyson | 0 | 1,931,892,304 | 2.6% | ||

| accelerator | 0 | 44,675,634,717 | 5% | ||

| mikepm74 | 0 | 48,109,235,636 | 35% | ||

| holbein81 | 0 | 51,331,707,207 | 4.42% | ||

| trevorpetrie | 0 | 2,190,931,782 | 2.6% | ||

| torico | 0 | 1,234,697,917 | 1.71% | ||

| tomiscurious | 0 | 6,727,320,801 | 2.4% | ||

| yangoldberg | 0 | 11,402,680,351 | 5.2% | ||

| therealwolf | 0 | 3,971,905,132,589 | 14% | ||

| mballesteros | 0 | 1,226,329,592 | 2.6% | ||

| minnowpowerup | 0 | 1,171,996,979 | 2.6% | ||

| revisesociology | 0 | 7,213,052,557 | 0.52% | ||

| plantstoplanks | 0 | 2,551,338,414 | 1.04% | ||

| diosarich | 0 | 988,163,126 | 17.5% | ||

| cryptononymous | 0 | 1,604,000,072 | 2.6% | ||

| upme | 0 | 2,674,857,339 | 2.6% | ||

| gotgame | 0 | 4,530,946,522 | 20% | ||

| critic-on | 0 | 919,250,417 | 17.5% | ||

| braveboat | 0 | 2,459,831,502 | 8% | ||

| jlsplatts | 0 | 9,172,373,111 | 1% | ||

| meno | 0 | 44,528,980,012 | 2.6% | ||

| buttcoins | 0 | 3,787,499,241 | 1.04% | ||

| toocurious | 0 | 1,767,299,556 | 2.6% | ||

| hanggggbeeee | 0 | 6,378,152,530 | 17.5% | ||

| fatkat | 0 | 1,382,164,730 | 2.59% | ||

| investegg | 0 | 186,750,759,047 | 5.86% | ||

| peaceandwar | 0 | 813,498,135 | 2.6% | ||

| enzor | 0 | 925,710,860 | 20% | ||

| marcoriccardi | 0 | 560,453,720 | 5.2% | ||

| liverpool-fan | 0 | 691,951,818 | 17.5% | ||

| carloserp-2000 | 0 | 17,269,291,247 | 100% | ||

| joetunex | 0 | 1,904,993,802 | 0.78% | ||

| battebilly | 0 | 529,015,178 | 2.6% | ||

| caladan | 0 | 4,422,976,248 | 1.9% | ||

| carlos84 | 0 | 8,798,121,872 | 25% | ||

| lays | 0 | 5,360,395,616 | 2.6% | ||

| gra | 0 | 3,609,345,592 | 40% | ||

| joseph1956 | 0 | 1,433,655,558 | 5% | ||

| eonwarped | 0 | 849,003,008,047 | 30% | ||

| postpromoter | 0 | 1,384,202,331,886 | 29% | ||

| diverse | 0 | 3,899,584,475 | 2.6% | ||

| omstavan | 0 | 8,107,533,397 | 100% | ||

| emrebeyler | 0 | 42,107,084,493 | 2% | ||

| bluefinstudios | 0 | 912,080,890 | 1.56% | ||

| steveconnor | 0 | 3,335,442,226 | 2.6% | ||

| sankysanket18 | 0 | 37,764,978,790 | 17.5% | ||

| smartsteem | 0 | 805,520,050,539 | 14% | ||

| drmake | 0 | 2,948,409,770 | 2.6% | ||

| danile666 | 0 | 6,237,890,086 | 4.94% | ||

| aboutcoolscience | 0 | 976,140,590 | 40% | ||

| elisonr13 | 0 | 1,134,116,788 | 5% | ||

| pechichemena | 0 | 630,213,530 | 1.04% | ||

| amestyj | 0 | 13,268,762,661 | 100% | ||

| sandracarrascal | 0 | 15,544,681,415 | 100% | ||

| skycae | 0 | 647,780,666 | 5.2% | ||

| itchyfeetdonica | 0 | 2,275,294,211 | 1.04% | ||

| egotheist | 0 | 736,455,728 | 4% | ||

| kenadis | 0 | 10,952,145,222 | 40% | ||

| steempsych | 0 | 1,707,481,063 | 40% | ||

| madridbg | 0 | 766,335,712 | 15% | ||

| robotics101 | 0 | 11,824,549,676 | 40% | ||

| marcolino76 | 0 | 988,559,189 | 2.6% | ||

| kamchore | 0 | 155,877,639,058 | 100% | ||

| mikitaly | 0 | 1,357,673,631 | 30% | ||

| gentleshaid | 0 | 88,306,353,399 | 100% | ||

| rpcaceres | 0 | 6,872,538,836 | 40% | ||

| tomatom | 0 | 2,183,999,886 | 17.5% | ||

| danaedwards | 0 | 674,187,059 | 5.2% | ||

| sco | 0 | 47,353,878,107 | 40% | ||

| ennyta | 0 | 993,997,127 | 50% | ||

| stahlberg | 0 | 1,192,061,020 | 2.6% | ||

| gabrielatravels | 0 | 10,671,668,782 | 7% | ||

| vjap55 | 0 | 957,240,519 | 100% | ||

| eliaschess333 | 0 | 3,394,563,391 | 50% | ||

| iamjadeline | 0 | 1,810,115,997 | 0.78% | ||

| intrepidphotos | 0 | 372,592,410,173 | 8% | ||

| hijosdelhombre | 0 | 46,687,310,971 | 50% | ||

| steemvault | 0 | 1,055,687,057 | 5.2% | ||

| shinedojo | 0 | 640,064,657 | 5.2% | ||

| fragmentarion | 0 | 7,932,805,180 | 40% | ||

| gaming.yer | 0 | 2,000,758,358 | 100% | ||

| bennettitalia | 0 | 1,211,015,542 | 1.3% | ||

| nealmcspadden | 0 | 27,004,582,224 | 2% | ||

| hadji | 0 | 13,347,840,148 | 100% | ||

| utube | 0 | 2,748,204,820 | 5.2% | ||

| bala41288 | 0 | 30,995,860,164 | 10% | ||

| wanderlass | 0 | 582,805,193 | 2.6% | ||

| purefood | 0 | 12,789,934,923 | 2% | ||

| terrylovejoy | 0 | 7,300,887,812 | 16% | ||

| sincroniadivina | 0 | 1,753,366,504 | 5% | ||

| talli-art | 0 | 455,682,254 | 5.2% | ||

| neneandy | 0 | 5,973,160,396 | 5.2% | ||

| pab.ink | 0 | 13,171,936,924 | 20% | ||

| sportscontest | 0 | 1,883,399,337 | 5.2% | ||

| giddyupngo | 0 | 826,015,363 | 2.6% | ||

| videosteemit | 0 | 4,091,975,721 | 5.2% | ||

| gribouille | 0 | 1,752,262,466 | 40% | ||

| pandasquad | 0 | 631,977,687 | 5.2% | ||

| leoumesh | 0 | 1,401,911,754 | 5.2% | ||

| stemng | 0 | 70,674,169,384 | 100% | ||

| rbalzan79 | 0 | 14,169,159,969 | 80% | ||

| lunaticpandora | 0 | 109,742,498,781 | 10% | ||

| debilog | 0 | 583,274,908 | 17.5% | ||

| kingabesh | 0 | 1,969,404,617 | 50% | ||

| miguelangel2801 | 0 | 796,864,349 | 50% | ||

| mproxima | 0 | 1,007,538,896 | 2.6% | ||

| gatolector | 0 | 5,418,513,018 | 17.5% | ||

| didic | 0 | 2,362,101,160 | 2.6% | ||

| ocd-witness | 0 | 436,190,679,820 | 35% | ||

| emiliomoron | 0 | 22,163,959,578 | 50% | ||

| beverages | 0 | 8,287,027,617 | 2.6% | ||

| dexterdev | 0 | 1,412,975,066 | 20% | ||

| sizandyola | 0 | 3,946,043,012 | 17.5% | ||

| verhp11 | 0 | 1,180,867,153 | 1% | ||

| oghie | 0 | 846,694,436 | 50% | ||

| photohunt | 0 | 6,670,935,438 | 5.2% | ||

| pkocjan | 0 | 895,727,200 | 1.6% | ||

| geopolis | 0 | 2,655,141,133 | 40% | ||

| robertbira | 0 | 4,311,975,451 | 10% | ||

| stk-g | 0 | 1,027,211,026 | 5.2% | ||

| the.chiomz | 0 | 1,118,673,615 | 55% | ||

| alexdory | 0 | 42,933,101,146 | 40% | ||

| takowi | 0 | 66,658,540,812 | 5.2% | ||

| flugschwein | 0 | 16,086,650,980 | 34% | ||

| lightflares | 0 | 5,176,256,511 | 2.6% | ||

| cyprianj | 0 | 19,409,629,946 | 100% | ||

| citimillz | 0 | 3,366,538,382 | 2.6% | ||

| doikao | 0 | 30,710,265,966 | 5.2% | ||

| francostem | 0 | 5,552,424,385 | 40% | ||

| kitalee | 0 | 2,584,677,402 | 2.6% | ||

| endopediatria | 0 | 695,806,150 | 20% | ||

| forester-joe | 0 | 4,957,411,247 | 10.14% | ||

| vicesrus | 0 | 6,815,321,101 | 2.6% | ||

| croctopus | 0 | 1,570,410,912 | 100% | ||

| zipporah | 0 | 2,614,809,425 | 1.04% | ||

| joelagbo | 0 | 9,488,652,791 | 50% | ||

| idkpdx | 0 | 292,028,224 | 2.6% | ||

| superlotto | 0 | 7,572,638,893 | 5.2% | ||

| djoi | 0 | 4,843,081,724 | 50% | ||

| norwegianbikeman | 0 | 6,453,068,585 | 5% | ||

| positiveninja | 0 | 721,667,449 | 2.6% | ||

| miroslavrc | 0 | 25,323,024,114 | 17.5% | ||

| bscrypto | 0 | 9,446,236,867 | 2.6% | ||

| vonaurolacu | 0 | 1,281,517,472 | 2.6% | ||

| movingman | 0 | 2,422,004,981 | 20% | ||

| delpilar | 0 | 934,959,443 | 25% | ||

| proto26 | 0 | 644,181,796 | 5.2% | ||

| scottcbusiness | 0 | 1,662,951,045 | 2.6% | ||

| tomastonyperez | 0 | 17,118,554,130 | 50% | ||

| marcus0alameda | 0 | 542,724,382 | 30% | ||

| bil.prag | 0 | 840,204,199 | 0.26% | ||

| elvigia | 0 | 11,215,576,001 | 50% | ||

| camiloferrua | 0 | 787,942,936 | 2.86% | ||

| bestboom | 0 | 9,132,785,094 | 2% | ||

| sanderjansenart | 0 | 2,665,653,123 | 2.6% | ||

| vittoriozuccala | 0 | 1,568,807,405 | 2.6% | ||

| qberry | 0 | 2,843,740,598 | 2.6% | ||

| frissonsteemit | 0 | 1,036,028,839 | 2.6% | ||

| lesmouths-travel | 0 | 2,395,931,630 | 30% | ||

| rambutan.art | 0 | 1,274,970,355 | 5.2% | ||

| greddyforce | 0 | 1,819,746,834 | 1.92% | ||

| flyerchen | 0 | 683,597,812 | 2.6% | ||

| juanmanuellopez1 | 0 | 1,519,645,433 | 8% | ||

| braaiboy | 0 | 9,144,735,258 | 3.9% | ||

| carolinacardoza | 0 | 4,808,133,356 | 5% | ||

| freddio | 0 | 12,108,662,149 | 15% | ||

| blainjones | 0 | 1,108,877,769 | 1.04% | ||

| gadrian | 0 | 53,673,723,576 | 35% | ||

| tonimontana | 0 | 295,496,255 | 11.43% | ||

| jordangerder | 0 | 943,064,618 | 5% | ||

| themightyvolcano | 0 | 1,771,187,389 | 2% | ||

| gifty-e | 0 | 797,705,703 | 100% | ||

| scruffy23 | 0 | 19,996,586,835 | 50% | ||

| eniolw | 0 | 2,624,615,481 | 100% | ||

| de-stem | 0 | 24,016,869,094 | 39.6% | ||

| serylt | 0 | 1,804,229,796 | 39.2% | ||

| misia1979 | 0 | 708,920,681 | 2.6% | ||

| josedelacruz | 0 | 9,146,332,936 | 50% | ||

| joseangelvs | 0 | 519,661,853 | 100% | ||

| payroll | 0 | 78,076,502,501 | 2% | ||

| andrewharland | 0 | 2,399,341,562 | 5.2% | ||

| mariusfebruary | 0 | 12,346,303,044 | 2.08% | ||

| outtheshellvlog | 0 | 753,196,282 | 2.6% | ||

| hansdewet | 0 | 1,053,540,031 | 5.2% | ||

| menoski | 0 | 11,197,973,072 | 50% | ||

| meanbees | 0 | 71,901,843,820 | 20% | ||

| srijana-gurung | 0 | 1,059,490,053 | 2.6% | ||

| feedmytwi | 0 | 567,758,386 | 7% | ||

| incubot | 0 | 5,371,503,569 | 3.9% | ||

| deholt | 0 | 2,313,906,255 | 34% | ||

| playdice | 0 | 711,042,212 | 1.95% | ||

| gwilberiol | 0 | 9,420,676,837 | 4.68% | ||

| edanya | 0 | 793,168,079 | 2.6% | ||

| pladozero | 0 | 79,148,059,048 | 10% | ||

| nateaguila | 0 | 296,659,912,085 | 8% | ||

| stevenwood | 0 | 1,247,082,034 | 1.73% | ||

| enforcer48 | 0 | 123,742,284,138 | 15% | ||

| temitayo-pelumi | 0 | 3,889,340,451 | 50% | ||

| andrick | 0 | 866,365,209 | 50% | ||

| yusvelasquez | 0 | 5,868,362,002 | 50% | ||

| motherofalegend | 0 | 5,184,893,154 | 20% | ||

| doctor-cog-diss | 0 | 1,615,373,465 | 40% | ||

| musicvoter2 | 0 | 3,975,565,220 | 1% | ||

| marcuz | 0 | 1,324,901,032 | 20% | ||

| pialejoana | 0 | 624,197,141 | 2.6% | ||

| itastem | 0 | 6,727,600,397 | 40% | ||

| wolfofnostreet | 0 | 571,002,285 | 2.6% | ||

| acont | 0 | 19,861,435,723 | 75% | ||

| uche-nna | 0 | 5,176,618,530 | 4.16% | ||

| schroders | 0 | 2,065,693,853 | 1.56% | ||

| anaestrada12 | 0 | 22,283,558,531 | 100% | ||

| dzoji | 0 | 858,734,493 | 5.2% | ||

| darkfemme | 0 | 5,234,312,147 | 40% | ||

| we-are-lucky | 0 | 6,583,801,618 | 33.7% | ||

| cheese4ead | 0 | 1,064,823,968 | 2.6% | ||

| longer | 0 | 603,453,037 | 1.3% | ||

| blewitt | 0 | 6,486,096,619 | 0.26% | ||

| drsensor | 0 | 629,587,383 | 24% | ||

| ilovecryptopl | 0 | 853,241,121 | 4.16% | ||

| mindblast | 0 | 2,975,626,510 | 2.6% | ||

| urdreamscometrue | 0 | 9,703,489,080 | 60% | ||

| ocdb | 0 | 25,822,952,665,880 | 29% | ||

| bflanagin | 0 | 3,221,416,832 | 2.6% | ||

| ubaldonet | 0 | 1,863,630,788 | 70% | ||

| sadbear | 0 | 995,283,719 | 2.6% | ||

| dalz | 0 | 2,965,315,652 | 1% | ||

| goblinknackers | 0 | 154,847,859,166 | 4% | ||

| zuerich | 0 | 507,839,153,639 | 10% | ||

| jk6276 | 0 | 0 | 1% | ||

| yaelg | 0 | 758,720,562 | 1.56% | ||

| orthodoxnudism | 0 | 492,621,343 | 2.6% | ||

| kylealex | 0 | 4,642,982,350 | 10% | ||

| dlike | 0 | 24,100,415,406 | 2% | ||

| minimining | 0 | 904,025,184 | 2.6% | ||

| loveforlove | 0 | 6,036,702,556 | 100% | ||

| lupafilotaxia | 0 | 92,670,879,264 | 75% | ||

| voxmortis | 0 | 1,060,956,779 | 0.5% | ||

| spoke | 0 | 9,002,787,502 | 4.16% | ||

| fran.frey | 0 | 4,214,477,344 | 50% | ||

| perpetuum-lynx | 0 | 1,194,790,613 | 39.2% | ||

| thurllanie | 0 | 708,067,869 | 50% | ||

| andreasalas | 0 | 1,678,687,605 | 10% | ||

| gordonramzy | 0 | 555,835,163 | 100% | ||

| engrave | 0 | 26,918,502,463 | 1.6% | ||

| adoptad0 | 0 | 604,388,049 | 40% | ||

| pboulet | 0 | 6,637,060,977 | 20% | ||

| belkisa758 | 0 | 6,192,473,949 | 10% | ||

| marcocasario | 0 | 8,452,466,727 | 2.6% | ||

| bobby.madagascar | 0 | 723,667,362 | 1% | ||

| oakshieldholding | 0 | 368,798,365 | 100% | ||

| stem-espanol | 0 | 80,133,121,030 | 100% | ||

| laissez-faire | 0 | 71,119,643 | 100% | ||

| babysavage | 0 | 49,957,147,569 | 100% | ||

| aleestra | 0 | 9,909,729,676 | 80% | ||

| knightbjj | 0 | 1,082,880,418 | 3.9% | ||

| the.success.club | 0 | 2,434,868,712 | 2.6% | ||

| chickenmeat | 0 | 1,072,808,151 | 2.6% | ||

| javier.dejuan | 0 | 3,338,325,355 | 40% | ||

| balticbadger | 0 | 5,511,196,513 | 25% | ||

| amansharma555 | 0 | 595,961,049 | 100% | ||

| meanroosterfarm | 0 | 8,323,240,241 | 20% | ||

| tommyl33 | 0 | 645,146,491 | 2.6% | ||

| teemike | 0 | 824,104,117 | 50% | ||

| embot | 0 | 528,761,894 | 100% | ||

| scienze | 0 | 8,351,949,936 | 40% | ||

| scienza | 0 | 8,440,026,024 | 40% | ||

| merlin7 | 0 | 20,653,461,994 | 1.6% | ||

| besheda | 0 | 601,609,994 | 20% | ||

| dubignyp | 0 | 1,031,025,498 | 20% | ||

| brianoflondon | 0 | 10,427,469,545 | 0.78% | ||

| giulyfarci52 | 0 | 1,722,948,742 | 50% | ||

| pushpedal | 0 | 3,190,752,902 | 17.5% | ||

| esthersanchez | 0 | 3,474,423,808 | 40% | ||

| byercatire | 0 | 2,490,705,064 | 37% | ||

| followjohngalt | 0 | 14,365,200,250 | 2% | ||

| universoperdido | 0 | 9,689,279,461 | 32.5% | ||

| solarphasing | 0 | 534,271,753 | 5% | ||

| the-rhapsodist | 0 | 18,008,979,414 | 40% | ||

| cowpatty | 0 | 822,027,770 | 20% | ||

| stem.witness | 0 | 98,107,544,639 | 40% | ||

| empressteemah | 0 | 2,677,949,138 | 100% | ||

| edriseur | 0 | 517,856,537 | 35% | ||

| elkaos | 0 | 2,285,704,095 | 100% | ||

| variedades | 0 | 3,798,613,101 | 11.6% | ||

| robmojo | 0 | 9,651,903,872 | 4% | ||

| double-negative | 0 | 529,054,868 | 20% | ||

| wilmer14molina | 0 | 3,836,294,099 | 50% | ||

| kork75 | 0 | 2,376,990,293 | 17.5% | ||

| angelik-a | 0 | 931,250,638 | 5% | ||

| vaultec | 0 | 3,060,057,569 | 12% | ||

| steemstorage | 0 | 5,296,784,970 | 5.2% | ||

| jtm.support | 0 | 2,951,530,258 | 40% | ||

| permaculturedude | 0 | 759,005,378 | 2% | ||

| agent14 | 0 | 11,233,439,911 | 29.75% | ||

| loliver | 0 | 1,792,866,903 | 5.2% | ||

| mazima | 0 | 1,145,118,921 | 17.5% | ||

| crowdwitness | 0 | 32,978,656,105 | 20% | ||

| hairgistix | 0 | 2,609,601,370 | 2.6% | ||

| goodcontentbot | 0 | 806,692,885 | 15% | ||

| rem-steem | 0 | 2,115,975,137 | 1.04% | ||

| limka | 0 | 362,659,629 | 100% | ||

| abbenay | 0 | 1,106,701,215 | 5.25% | ||

| cryptological | 0 | 610,115,512 | 2.6% | ||

| breakout101 | 0 | 595,908,248 | 2.6% | ||

| ficcion | 0 | 4,408,590,748 | 37% | ||

| samuel.steem | 0 | 920,717,256 | 100% | ||

| jackramsey | 0 | 713,974,342 | 3.64% | ||

| ambifokus | 0 | 573,949,655 | 0.78% | ||

| paolo.senegal | 0 | 1,306,934,965 | 100% | ||

| mfblack | 0 | 10,327,524,376 | 1.9% | ||

| elements5 | 0 | 628,528,306 | 2.6% | ||

| issymarie | 0 | 8,284,996,504 | 20% | ||

| steemitfn | 0 | 1,144,037,121 | 40% | ||

| epicdice | 0 | 31,072,181,214 | 4.2% | ||

| yiobri | 0 | 1,361,496,828 | 5% | ||

| iamsaray | 0 | 676,441,151 | 2.6% | ||

| gadrian-sp | 0 | 2,456,718,542 | 35% | ||

| robibasa | 0 | 12,121,858,881 | 10% | ||

| scholaris | 0 | 28,104,218,374 | 10% | ||

| beerlover | 0 | 20,053,813,767 | 17.5% | ||

| yourfuture | 0 | 3,719,730,917 | 28% | ||

| fractalfrank | 0 | 6,550,704,425 | 2.6% | ||

| victartex | 0 | 1,268,817,623 | 40% | ||

| ocd-accountant | 0 | 2,218,674,860 | 14% | ||

| quantumdeveloper | 0 | 2,414,480,788 | 50% | ||

| leighscotford | 0 | 641,492,273 | 1.45% | ||

| quintaesencia | 0 | 7,688,224,505 | 100% | ||

| walterprofe | 0 | 38,952,369,650 | 100% | ||

| afarina46 | 0 | 1,093,105,857 | 20% | ||

| titan-c | 0 | 1,504,537,775 | 5.2% | ||

| nalacanecorso | 0 | 1,108,120,188 | 100% | ||

| mariolbi | 0 | 739,889,313 | 5% | ||

| mind.force | 0 | 778,590,911 | 1.3% | ||

| triplea.bot | 0 | 675,554,927 | 2% | ||

| gassa28 | 0 | 747,406,008 | 20% | ||

| steem.leo | 0 | 22,161,697,861 | 2% | ||

| reggaesteem | 0 | 679,012,843 | 5% | ||

| stemgeeks | 0 | 14,584,728,481 | 100% | ||

| freddio.sport | 0 | 3,455,713,662 | 15% | ||

| stemcuration | 0 | 3,700,054,939 | 100% | ||

| partitura.ccc | 0 | 293,315,851 | 100% | ||

| liambu | 0 | 1,891,105,167 | 20% | ||

| asteroids | 0 | 2,118,101,774 | 1.8% | ||

| capp | 0 | 7,565,364,412 | 50% | ||

| abh12345.stem | 0 | 713,690,168 | 100% | ||

| nazer | 0 | 4,268,428,947 | 20% | ||

| btc4breackfast | 0 | 1,700,761,834 | 100% | ||

| janaveda | 0 | 102,017,630,367 | 100% | ||

| caciques | 0 | 67,670,807,109 | 37% | ||

| maxuvd | 0 | 20,350,767,024 | 6% | ||

| lcrestrepo | 0 | 1,020,476,735 | 20% | ||

| mister.reatard | 0 | 869,845,519 | 12.5% | ||

| urtrailer | 0 | 1,193,067,490 | 0.25% | ||

| omegarojo827 | 0 | 1,732,412,896 | 40% | ||

| stemd | 0 | 333,296,530 | 100% | ||

| entrepreneur.one | 0 | 2,308,386,227 | 100% | ||

| askari.ccc | 0 | 194,110,604 | 15.6% | ||

| joshmania | 0 | 11,753,562,447 | 10% | ||

| steemstem-trig | 0 | 3,133,556,708 | 40% | ||

| tonimontana.neo | 0 | 0 | 0.77% | ||

| hispapro | 0 | 12,322,584,603 | 10% | ||

| herzinfuck | 0 | 2,297,387,872 | 2.6% | ||

| axel-blaze | 0 | 7,669,647,819 | 0.52% | ||

| nucleo-fse | 0 | 7,742,146,604 | 40% | ||

| gerbo | 0 | 0 | 2% | ||

| pecoshop | 0 | 1,747,404,640 | 100% | ||

| steemlondon | 0 | 554,844,177 | 6% | ||

| ibt-survival | 0 | 38,918,516,745 | 10% | ||

| stem.curate | 0 | 861,773,040 | 100% | ||

| yourtop3 | 0 | 8,121,143,562 | 2.08% | ||

| delilhavores | 0 | 951,965,804 | 4% | ||

| tariqul.bibm | 0 | 681,700,297 | 2.6% | ||

| roamingsparrow | 0 | 4,973,529,168 | 3.9% | ||

| boomalex | 0 | 2,265,486,852 | 100% | ||

| toni.ccc | 0 | 27,829,164 | 1.1% | ||

| ribary | 0 | 619,606,249 | 1% | ||

| steemlatintrail | 0 | 3,355,595,440 | 100% | ||

| machete9595 | 0 | 2,203,212,811 | 100% | ||

| jeffmackinnon | 0 | 862,759,913 | 8% | ||

| neoado | 0 | 3,259,701,972 | 100% | ||

| toni.pal | 0 | 0 | 1.41% | ||

| crypto.currents | 0 | 692,281,657 | 100% | ||

| im-ridd | 0 | 713,881,027 | 2.6% | ||

| bilpcoinbpc | 0 | 1,355,260,726 | 15% | ||

| disagio.gang | 0 | 1,345,582,458 | 5.2% | ||

| mice-k | 0 | 9,995,923,257 | 2% | ||

| mengene | 0 | 1,509,559,091 | 17.5% | ||

| goldstreet | 0 | 132,584,725 | 5.2% | ||

| mehmetfix | 0 | 908,607,919 | 1.56% | ||

| theisacoin | 0 | 994,431,992 | 10% | ||

| dpend.active | 0 | 7,001,857,734 | 7% | ||

| andreina57 | 0 | 750,146,710 | 20% | ||

| almightymelon | 0 | 1,061,533,510 | 2.6% | ||

| fengchao | 0 | 3,950,567,924 | 3% | ||

| hornetsnest | 0 | 3,854,889,050 | 2.6% | ||

| thepeakstudio | 0 | 1,223,319,648 | 2.6% | ||

| stemsocial | 0 | 8,284,927,003 | 40% | ||

| hive.consultant | 0 | 6,814,613,697 | 4.16% | ||

| manwojciech | 0 | 513,940,662 | 5.2% | ||

| visionaer3003 | 0 | 65,869,487,116 | 2% | ||

| gitplait | 0 | 76,833,485,326 | 100% | ||

| edwin-doncel | 0 | 4,133,090,401 | 40% | ||

| polish.hive | 0 | 5,439,201,070 | 2% | ||

| peterpanpan | 0 | 950,399,978 | 1.04% | ||

| dcityrewards | 0 | 64,313,758,368 | 2% | ||

| freakeao | 0 | 714,773,792 | 1.56% | ||

| meppij | 0 | 2,827,328,915 | 0.78% | ||

| hf19 | 0 | 43,362,228,684 | 100% | ||

| hiveonboard | 0 | 14,008,842,663 | 10.5% | ||

| kiemis | 0 | 1,791,846,863 | 0.39% | ||

| lyubo19 | 0 | 1,773,347,539 | 4.42% | ||

| iameden | 0 | 1,377,480,155 | 17.5% | ||

| rihc94 | 0 | 1,194,536,328 | 2.6% | ||

| shinyrygaming | 0 | 1,903,310,084 | 20% | ||

| hive-101493 | 0 | 1,494,964,556 | 20% | ||

| poshbot | 0 | 39,458,623,261 | 50% | ||

| jsalvage | 0 | 572,548,278 | 20% | ||

| hivecur | 0 | 51,387,943,151 | 2% | ||

| mtzrene | 0 | 4,085,120,630 | 100% | ||

| wristwatch12 | 0 | 619,847,449 | 17.5% | ||

| asa-raw | 0 | 718,948,246,803 | 20% | ||

| adolfom | 0 | 2,843,307,960 | 100% | ||

| malenavargas | 0 | 9,637,324,225 | 100% | ||

| syberia | 0 | 657,494,799 | 17.5% | ||

| hatschi0773 | 0 | 7,382,899,492 | 2% | ||

| facilitymanager | 0 | 4,391,198,357 | 40% | ||

| libbi | 0 | 741,115,196 | 17.5% | ||

| zoeanavid | 0 | 937,952,894 | 17.5% | ||

| questcrypto | 0 | 10,519,804,400 | 1.3% | ||

| chaodietas | 0 | 1,052,898,838 | 100% | ||

| discohedge | 0 | 601,547,066 | 1% | ||

| usainvote | 0 | 1,433,658,402,416 | 10% | ||

| dagobert007 | 0 | 74,304,122,102 | 2% | ||

| bitcome | 0 | 900,662,440 | 14.5% | ||

| crazy-science | 0 | 1,211,239,573 | 100% |

https://twitter.com/CARLOSJB84/status/1306385955625070592

| author | poshbot |

|---|---|

| permlink | re-how-petroleum-well-completion-and-workover-fluids--1600296592-20200917t001424z |

| category | hive-196387 |

| json_metadata | "{"app": "beem/0.24.8"}" |

| created | 2020-09-17 00:14:24 |

| last_update | 2020-09-17 00:14:24 |

| depth | 1 |

| children | 0 |

| last_payout | 2020-09-24 00:14:24 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 0.000 HBD |

| curator_payout_value | 0.000 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 57 |

| author_reputation | 5,554,335,374,496 |

| root_title | "How Petroleum Well Completion and Workover Fluids are Used" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 99,666,961 |

| net_rshares | 0 |

<div class='text-justify'> <div class='pull-left'> <img src='https://stem.openhive.network/images/stemsocialsupport7.png'> </div> Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us! Please consider <a href="https://hivesigner.com/sign/update-proposal-votes?proposal_ids=%5B91%5D&approve=true">supporting our funding proposal</a>, <a href="https://hivesigner.com/sign/account_witness_vote?approve=1&witness=stem.witness">approving our witness</a> (@stem.witness) or delegating to the @stemsocial account (for some ROI). Thanks for using the <a href='https://stem.openhive.network'>STEMsocial app</a> and including @stemsocial as a beneficiary, which give you stronger support. <br /> <br />

| author | steemstem |

|---|---|

| permlink | re-carlos84-how-petroleum-well-completion-and-workover-fluids--1600296592-20200918t123129270z |

| category | hive-196387 |

| json_metadata | {"app":"stemsocial"} |

| created | 2020-09-18 12:31:30 |

| last_update | 2020-09-18 12:31:30 |

| depth | 1 |

| children | 1 |

| last_payout | 2020-09-25 12:31:30 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 0.000 HBD |

| curator_payout_value | 0.000 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 776 |

| author_reputation | 262,017,435,115,313 |

| root_title | "How Petroleum Well Completion and Workover Fluids are Used" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 99,693,123 |

| net_rshares | 0 |

Thank you for supporting StemSocial, always reiterating the commitment to the community. Greetings

| author | carlos84 |

|---|---|

| permlink | qgvq3d |

| category | hive-196387 |

| json_metadata | {"app":"hiveblog/0.1"} |

| created | 2020-09-19 00:16:30 |

| last_update | 2020-09-19 00:16:30 |

| depth | 2 |

| children | 0 |

| last_payout | 2020-09-26 00:16:30 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 0.000 HBD |

| curator_payout_value | 0.000 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 98 |

| author_reputation | 353,218,698,404,153 |

| root_title | "How Petroleum Well Completion and Workover Fluids are Used" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 99,702,711 |

| net_rshares | 0 |

hiveblocks

hiveblocks