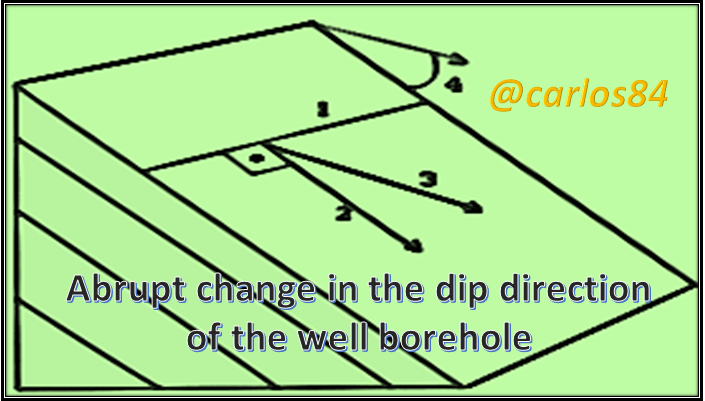

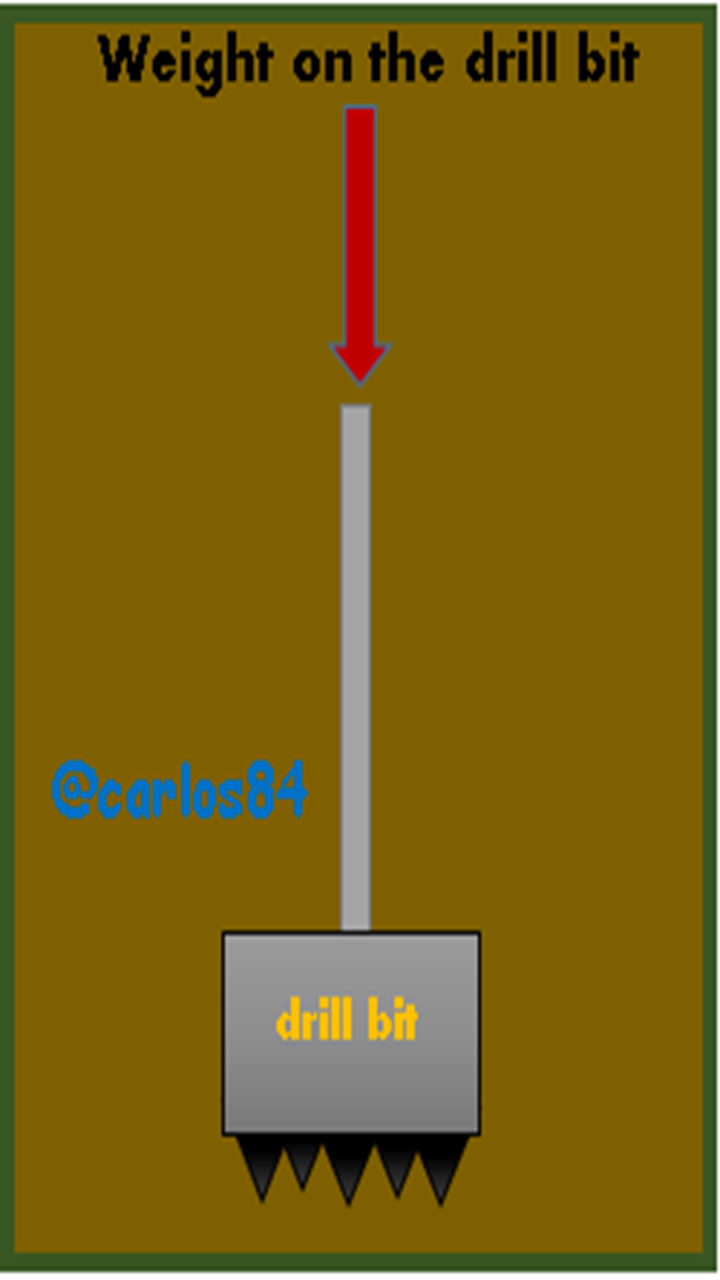

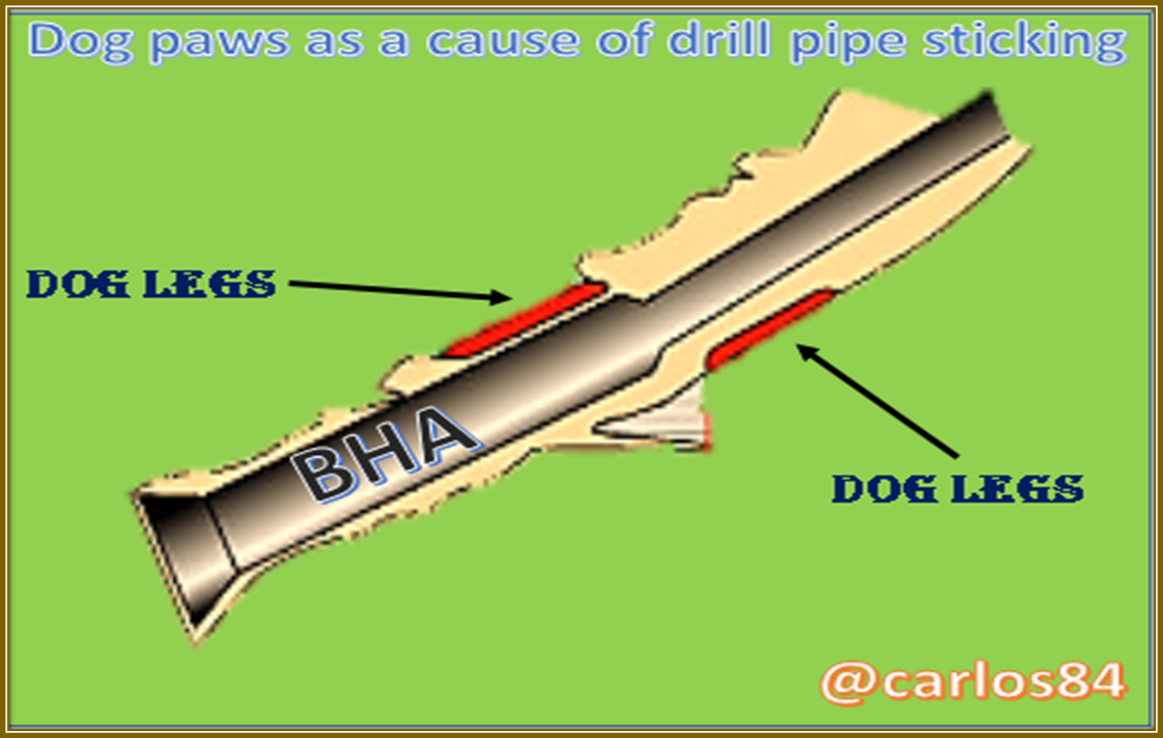

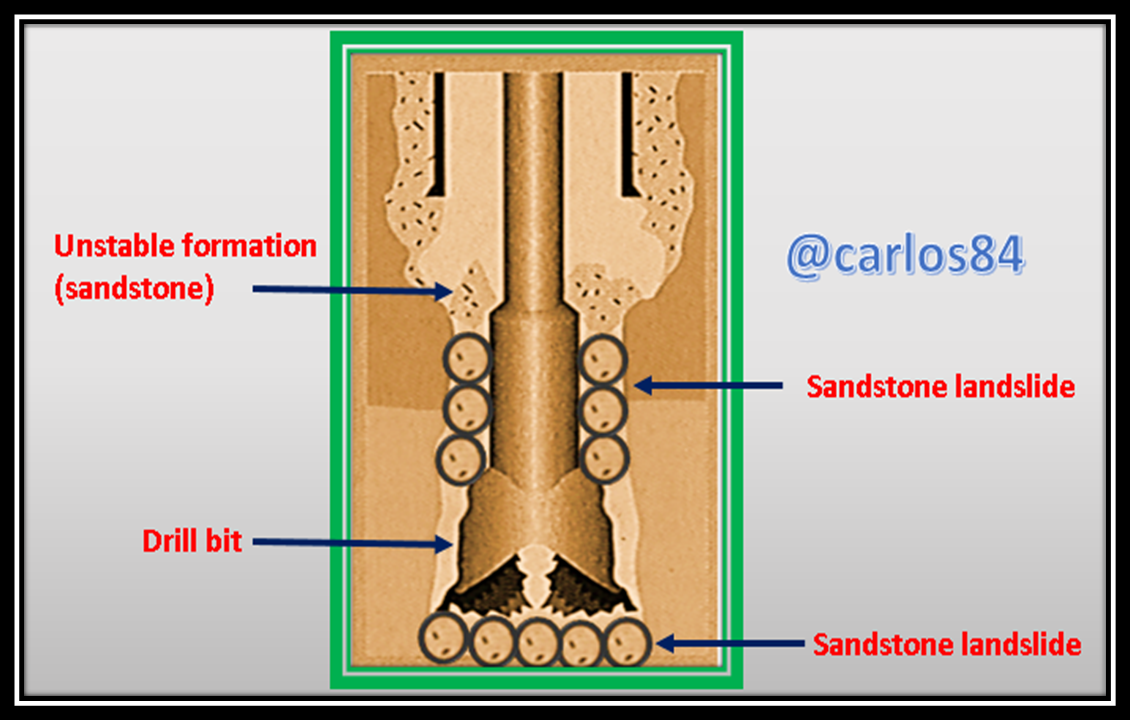

<div class="text-justify">  Hello friends of the scientific and academic community of hive, on this occasion I want to share with all of you unpublished information relevant to the problems that we can find when we are drilling an oil well. ### ***Introduction*** <p> It is common to imagine that when we are going to drill an oil and/or natural gas well we may encounter some problems that prevent us from the normal operation and progress in the drilling of wells and the future construction and completion of the same. Problems in well drilling range from the most common problems encountered in day-to-day operations to the most complex problems never seen before when compared to the problems and background of existing ones. Among the problems in the drilling of oil wells find: - Generation of doglegs and key seats. - Wellbore instability. - Loss of circulation and excessive downhole temperatures. As I mentioned before, there may be more problems that can be obtained when we are drilling an oil well, however these are the most common and under which we can build a vision to generate relevant solutions based on applied engineering to solve each of the problems mentioned. ### ***What is the problem with Doglegs in well drilling?*** <p> Certainly in directional drilling the objective is to deviate the direction of the hole with respect to the vertical, however in this deviation should not be obtained an angle of deviation greater than 3 degrees per 100 feet drilled. When the opposite happens, that is to say that the well begins to be drilled in a deviated manner and there are stretches in the drilling in which this deviation rate of 3 degrees per 100 feet is exceeded, then it generates what is known as dog legs, and where literally these dog legs are a problem in the drilling of wells because they generate a mechanical problem with the drill pipe, that is to say that the drill pipe sticks or lies on the walls of the hole caused by these dog legs. Now perhaps many of you reading this article are wondering: ***What causes these dog legs in the formation while drilling?*** There are many factors at play, however among the most common are: - ***Change in dip:*** when the directionality of the well has already been planned consequent to the directional planning, the dip must be followed strictly as planned, any deviation from the dip could trigger the generation of doglegs that cause the drill pipe to stick to the bottom of the well.  ><sup>Author of the image: @carlos84. Elaborated using Microsoft Powerpoint design tools.</sup> - ***Change in weight applied to the drill bit:*** when we increase the weight on the bit abruptly, even if we increase the weight on the bit above what the drilling program tells us, we can increase the drilling speed and therefore not have a controlled drilling, bringing as a consequence the generation of dog legs.  ><sup>Author of the image: @carlos84. Elaborated using Microsoft Powerpoint design tools.</sup> When we analyze the doglegs as the main cause of drill pipe sticking downhole, we must agree that even the generation of a severe dogleg can be the indication of a pipe sticking, which leads us to conclude that this is a problem that must be controlled in directional drilling, so the deviation rate of 3 degrees per 100 feet drilled should not be exceeded. This is such a serious problem in the drilling and construction of an oil well, that even the doglegs do not only cause a problem in that the drill pipe sticks while drilling, but it is also an impediment to lower the casing in the hole since it can get stuck in the descent.  ><sup>Author of the image: @carlos84. Elaborated using Microsoft Powerpoint design tools.</sup> In the previous image we can see a clear example of a pipe sticking due to dog legs, generally the dog legs cause the pipe to stick in the bottom hole assembly (BHA), this is because the bottom hole assembly has a larger diameter than the drill pipe, therefore it is at that point where the pipe sticks to the subsurface formation. Another problem caused by doglegs are key seats, these key seats or key seats are formed as a result of the dragging action of the drill pipe every time the pipe makes a trip up and down the well, so it can be deduced that the only way to avoid generating key seats is not generating doglegs in the well. ### ***Other problems encountered in the drilling of wells*** <p> A problem that we can find in the drilling of wells is the instability of the lithological formation of the subsoil, although these problems of instability of the hole are not associated with human errors in planning, certainly if we can add that we can abide by some recommendations to minimize its negative impact on the progress of drilling. Hole instability occurs when the lithological formations that we get while we are drilling and deepening in the hole collapse or swell. For example if we are drilling at a certain depth in the well and we encounter a shale section, we have to be very aware that shales swell when they are under the presence of water, so it is advisable to drill in that section with an oil based drilling fluid and not a water based drilling fluid, because if the drilling fluid is water based the shales swell and can cause the drill pipe to get stuck at the bottom of the well. Sandstones are quite soft and unstable, so in a sandstone section it is recommended to drill with a flow rate of drilling fluid not so high, all with the aim of causing collapse of the sandstone section, if you drill with a very high flow rate in a sandstone section can generate a sticking of pipe by packing, which is when all the collapse ad sandstone falls to the bottom of the hole causing the pipe string stops rotating.  ><sup>Author of the image: @carlos84. Elaborated using Microsoft Powerpoint design tools.</sup> ### ***Is loss of drilling fluid circulation a problem in well drilling?*** <p> Circulation losses of the drilling fluid is also a problem that can stop the drilling of the well and can even cause the well to be lost. Drilling fluid lost circulation is mainly due to two factors: - When a lithological section that has high permeability is crossed, when this happens the drilling fluid passes through the permeable formation causing all the drilling fluid to be lost, this causes the drill pipe to stick by differential sticking. The solution is to add materials and chemicals called anti-loss materials, with the intention of decreasing the permeability to the zone that is being traversed at that moment. - The other agent causing lost circulation is when there is a very high drilling fluid density, causing the fracture pressure of the formation to be exceeded, even when all the fluid is lost to the formation, the hydrostatic pressure may drop below the formation pressure, causing an onslaught and possible blowout of formation fluids to the surface. This causes not only economic losses but human losses as well.  <center><sup>[Image source. wikimedia commons: Public domain](https://en.wikipedia.org/wiki/File:Deepwater_Horizon_offshore_drilling_unit_on_fire_2010.jpg)</sup></center> ### ***Conclusion*** <p> The problems in the drilling of oil wells can be a reason for stopping the drilling and construction of an oil well, however, thanks to the knowledge that engineering can provide us, we can obtain solutions to each of these problems. Taking a clear and simple example, to avoid the sticking of drill pipe at the bottom of the hole that makes the oil industry lose so much money, you just have to take some precautions: - Maintain a rate in drilling speed in a controlled manner. - Drilling with an optimal flow rate, that is, not to exceed the maximum pump flow rate, because if it is exceeded it can cause landslides, especially in the lithology that is of little consolidated sands. - Maintain a deviation rate that does not exceed 3 degrees per 100 feet drilled, this with the intention of not originating dog legs, since as we saw they are the cause of pipe sticking due to mechanical action. In conclusion, the best way to avoid a problem in the drilling of wells is to establish a mode of operation that does not cause the causes that generate these problems, it is important not to act when the problem already exists, but to avoid generating at all costs the drilling problems explained in this article. ### ***<center>Reference consulted and recommended</center>*** <p> <center>[Drilling problems](https://wiki.aapg.org/Drilling_problems)</center> <center>[Pipe Sticking Prevention - Warning Signs: Torque](https://es.linkedin.com/pulse/prevenci%C3%B3n-pega-de-tuber%C3%ADa-se%C3%B1ales-advertencia-ayala-cort%C3%A9s)</center> </div>

| author | carlos84 |

|---|---|

| permlink | problems-in-the-drilling-of-oil-wells |

| category | hive-196387 |

| json_metadata | {"tags":["ocd","curangel","engineering","stem","palnet","neoxian","creativecoin"],"users":["carlos84"],"image":["https://images.hive.blog/DQmSiMDPptU8LyNbpoB1n5nUfCu1yRwJSYsMcGmtBVthWnr/image.png","https://images.hive.blog/DQmXkAxuXMJ83d94RZoQ2KS1QvP7WB94mwWTmQdmy3tcF9t/image.png","https://images.hive.blog/DQmciDf3KCDoeSvNivqEcx42qHG76pgdgHFFCkCyAQ9vHFt/image.png","https://images.hive.blog/DQmaT78u1VfnsrTSdvatZqU6DwAzf4doB4tEH2baBTh4Pui/image.png","https://images.hive.blog/DQmRwPn5oiwirUU8txi3bm5AXSLkxM847TnrPKefy3Znf74/image.png","https://images.hive.blog/DQmP6pxqNR17k9SDvDvyfbd9w2AimZ76B73SC5CdgHL5iRA/image.png"],"links":["https://en.wikipedia.org/wiki/File:Deepwater_Horizon_offshore_drilling_unit_on_fire_2010.jpg"],"app":"hiveblog/0.1","format":"markdown"} |

| created | 2021-04-01 13:13:03 |

| last_update | 2021-04-01 13:13:03 |

| depth | 0 |

| children | 2 |

| last_payout | 2021-04-08 13:13:03 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 11.064 HBD |

| curator_payout_value | 7.957 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 9,354 |

| author_reputation | 353,218,698,404,153 |

| root_title | "Problems in the drilling of oil wells" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 102,745,682 |

| net_rshares | 22,745,847,088,335 |

| author_curate_reward | "" |

| voter | weight | wgt% | rshares | pct | time |

|---|---|---|---|---|---|

| tombstone | 0 | 25,770,469,683 | 1.2% | ||

| simba | 0 | 1,002,345,320 | 1.35% | ||

| scalextrix | 0 | 618,998,981 | 1.35% | ||

| eric-boucher | 0 | 5,599,080,782 | 1.35% | ||

| thecryptodrive | 0 | 9,085,497,809 | 0.54% | ||

| mammasitta | 0 | 6,830,596,094 | 1.35% | ||

| skapaneas | 0 | 16,627,669,021 | 9% | ||

| gerber | 0 | 121,159,797,513 | 8% | ||

| roelandp | 0 | 507,432,870,850 | 15% | ||

| daan | 0 | 64,465,925,573 | 8% | ||

| ezzy | 0 | 95,671,997,140 | 8% | ||

| redpalestino | 0 | 1,016,173,752 | 100% | ||

| cloh76 | 0 | 1,797,747,088 | 1.35% | ||

| lichtblick | 0 | 1,282,646,050 | 0.81% | ||

| exyle | 0 | 63,799,459,771 | 8% | ||

| stephen.king989 | 0 | 4,331,382,895 | 1.35% | ||

| future24 | 0 | 1,311,294,223 | 1.35% | ||

| lemouth | 0 | 573,262,981,155 | 30% | ||

| netaterra | 0 | 127,900,465,201 | 5% | ||

| someguy123 | 0 | 162,460,805,591 | 8% | ||

| notconvinced | 0 | 15,841,002,625 | 30% | ||

| charlie777pt | 0 | 3,179,031,593 | 5% | ||

| alaqrab | 0 | 1,420,592,999 | 1.35% | ||

| lamouthe | 0 | 2,452,090,895 | 30% | ||

| uwelang | 0 | 10,798,034,103 | 1.35% | ||

| holoz0r | 0 | 2,520,808,345 | 4.05% | ||

| tfeldman | 0 | 2,385,721,165 | 1.35% | ||

| seckorama | 0 | 653,785,550 | 0.54% | ||

| ebargains | 0 | 542,355,878 | 2% | ||

| mcsvi | 0 | 101,060,088,104 | 50% | ||

| cnfund | 0 | 11,053,880,168 | 1.35% | ||

| michelle.gent | 0 | 1,297,519,866 | 0.54% | ||

| planosdeunacasa | 0 | 659,830,438 | 8% | ||

| curie | 0 | 354,196,293,112 | 2.7% | ||

| modernzorker | 0 | 1,377,408,590 | 1.89% | ||

| techslut | 0 | 67,287,982,971 | 12% | ||

| discovereurovelo | 0 | 4,061,648,374 | 1.35% | ||

| roguewriter | 0 | 1,878,291,795 | 15% | ||

| steemstem | 0 | 1,909,590,091,126 | 30% | ||

| tristancarax | 0 | 703,223,715 | 1.35% | ||

| yadamaniart | 0 | 863,061,159 | 1.35% | ||

| walterjay | 0 | 81,574,626,664 | 15% | ||

| valth | 0 | 3,226,142,134 | 15% | ||

| lastminuteman | 0 | 536,358,362 | 0.94% | ||

| driptorchpress | 0 | 1,289,446,055 | 1.35% | ||

| voter | 0 | 75,313,293 | 100% | ||

| barvon | 0 | 203,690,626 | 30% | ||

| dna-replication | 0 | 1,003,867,785 | 30% | ||

| privex | 0 | 2,705,617,918 | 2.7% | ||

| ambyr00 | 0 | 541,899,637 | 0.4% | ||

| gmedley | 0 | 535,745,231 | 1.35% | ||

| dhimmel | 0 | 433,244,306,534 | 7.5% | ||

| sokha | 0 | 6,456,387,291 | 50% | ||

| dune69 | 0 | 1,304,046,258 | 7.2% | ||

| federacion45 | 0 | 4,212,636,857 | 1.35% | ||

| iansart | 0 | 14,207,176,786 | 8% | ||

| forykw | 0 | 30,173,831,110 | 1.35% | ||

| mobbs | 0 | 50,612,008,096 | 15% | ||

| jagged | 0 | 1,148,766,898 | 0.54% | ||

| roomservice | 0 | 3,685,525,029 | 3% | ||

| fullofhope | 0 | 47,978,718,026 | 25% | ||

| sustainablyyours | 0 | 1,148,820,613 | 1.35% | ||

| erick1 | 0 | 1,092,408,900 | 1.35% | ||

| yehey | 0 | 41,588,684,755 | 2.7% | ||

| freetissues | 0 | 541,608,511 | 1.35% | ||

| samminator | 0 | 5,675,153,077 | 3% | ||

| robinhaney | 0 | 1,751,467,915 | 1.35% | ||

| alphacore | 0 | 15,286,988,028 | 2.41% | ||

| lorenzor | 0 | 9,993,055,095 | 50% | ||

| sam99 | 0 | 117,754,354,989 | 10.08% | ||

| alexander.alexis | 0 | 17,991,861,517 | 30% | ||

| ew-and-patterns | 0 | 94,890,416,517 | 9% | ||

| hhayweaver | 0 | 971,768,653 | 1.35% | ||

| gunthertopp | 0 | 34,174,630,055 | 0.62% | ||

| binkyprod | 0 | 1,075,804,084 | 1.35% | ||

| tngflx | 0 | 2,238,495,634 | 0.81% | ||

| ludmila.kyriakou | 0 | 2,082,516,894 | 9% | ||

| flatman | 0 | 2,012,857,340 | 2.7% | ||

| samest | 0 | 2,580,968,578 | 50% | ||

| minnowbooster | 0 | 1,268,425,188,735 | 20% | ||

| felt.buzz | 0 | 5,569,328,128 | 0.67% | ||

| howo | 0 | 860,576,925,848 | 30% | ||

| tsoldovieri | 0 | 3,025,607,372 | 15% | ||

| shitsignals | 0 | 3,862,410,152 | 8% | ||

| themarkymark | 0 | 2,454,636,613,979 | 8% | ||

| neumannsalva | 0 | 1,412,844,564 | 1.35% | ||

| stayoutoftherz | 0 | 40,176,431,087 | 1.35% | ||

| abigail-dantes | 0 | 11,177,520,005 | 30% | ||

| dine77 | 0 | 12,207,648,469 | 10% | ||

| dineroconopcion | 0 | 682,283,995 | 8% | ||

| zonguin | 0 | 2,563,700,374 | 7.5% | ||

| sciencevienna | 0 | 9,847,019,555 | 16.5% | ||

| joseg | 0 | 869,150,219 | 80% | ||

| zonabitcoin | 0 | 703,748,032 | 8% | ||

| jeanlucsr | 0 | 1,292,012,128 | 0.8% | ||

| sevillaespino | 0 | 27,477,704,923 | 8% | ||

| redrica | 0 | 1,330,323,512 | 1.35% | ||

| iamphysical | 0 | 7,427,297,136 | 90% | ||

| dipom98 | 0 | 531,223,850 | 1.35% | ||

| felixrodriguez | 0 | 776,637,415 | 15% | ||

| zyx066 | 0 | 3,999,763,943 | 1.35% | ||

| noboxes | 0 | 23,923,939,308 | 25% | ||

| betterthanhome | 0 | 3,322,528,071 | 2.7% | ||

| revo | 0 | 8,627,057,295 | 2.7% | ||

| felander | 0 | 39,335,950,970 | 8% | ||

| azulear | 0 | 4,814,687,277 | 100% | ||

| stickchumpion | 0 | 568,259,143 | 1.35% | ||

| noloafing | 0 | 986,194,886 | 7.5% | ||

| thelordsharvest | 0 | 3,652,430,006 | 2.7% | ||

| massivevibration | 0 | 18,688,366,905 | 30% | ||

| bradfordtennyson | 0 | 1,401,378,943 | 1.35% | ||

| accelerator | 0 | 82,317,927,991 | 5% | ||

| buildawhale | 0 | 5,927,968,309,835 | 8% | ||

| trevorpetrie | 0 | 1,142,926,258 | 1.35% | ||

| torico | 0 | 632,343,357 | 0.89% | ||

| yogacoach | 0 | 7,539,246,584 | 8% | ||

| tomiscurious | 0 | 21,306,387,285 | 4.9% | ||

| therealwolf | 0 | 586,389,398,398 | 4% | ||

| cryptononymous | 0 | 812,655,849 | 1.35% | ||

| upme | 0 | 798,121,532 | 1.35% | ||

| makerhacks | 0 | 25,135,964,509 | 8% | ||

| msp-foundation | 0 | 2,087,393,261 | 67.3% | ||

| meno | 0 | 10,661,417,788 | 1.35% | ||

| fatkat | 0 | 677,122,816 | 1.34% | ||

| investegg | 0 | 116,723,246,220 | 2.8% | ||

| enzor | 0 | 654,426,604 | 15% | ||

| carloserp-2000 | 0 | 4,302,524,924 | 100% | ||

| caladan | 0 | 883,983,114 | 7.2% | ||

| carlos84 | 0 | 42,965,373,869 | 100% | ||

| amritadeva | 0 | 728,998,067 | 1.35% | ||

| mejustandrew | 0 | 842,389,120 | 1.35% | ||

| omstavan | 0 | 6,422,345,029 | 100% | ||

| emrebeyler | 0 | 150,214,272,526 | 8% | ||

| steveconnor | 0 | 1,523,159,721 | 1.35% | ||

| sankysanket18 | 0 | 31,639,178,370 | 15% | ||

| smartsteem | 0 | 539,973,804,877 | 4% | ||

| drmake | 0 | 1,520,002,702 | 1.35% | ||

| cataluz | 0 | 920,336,931 | 1.35% | ||

| danile666 | 0 | 2,375,673,609 | 2.56% | ||

| aboutcoolscience | 0 | 3,367,663,319 | 30% | ||

| hendersonp | 0 | 3,130,972,857 | 8% | ||

| egotheist | 0 | 540,155,179 | 3% | ||

| kenadis | 0 | 7,611,589,625 | 30% | ||

| madridbg | 0 | 141,886,638,345 | 80% | ||

| gentleshaid | 0 | 63,698,814,586 | 100% | ||

| straykat | 0 | 1,838,953,925 | 1.35% | ||

| upmyvote | 0 | 5,693,766,938 | 8% | ||

| sco | 0 | 9,540,433,991 | 30% | ||

| ennyta | 0 | 954,266,007 | 50% | ||

| stahlberg | 0 | 583,638,542 | 1.35% | ||

| gabrielatravels | 0 | 1,032,504,646 | 0.54% | ||

| carn | 0 | 683,253,796 | 2.7% | ||

| eliaschess333 | 0 | 3,129,645,342 | 50% | ||

| branbello | 0 | 2,499,146,872 | 15% | ||

| iamjadeline | 0 | 956,211,247 | 0.4% | ||

| intrepidphotos | 0 | 58,086,729,055 | 22.5% | ||

| aiziqi | 0 | 736,859,938 | 5% | ||

| steemvault | 0 | 964,001,643 | 2.7% | ||

| fragmentarion | 0 | 6,784,591,382 | 30% | ||

| bennettitalia | 0 | 956,351,951 | 0.67% | ||

| nealmcspadden | 0 | 8,624,215,101 | 8% | ||

| hadji | 0 | 37,745,049,869 | 100% | ||

| utube | 0 | 2,090,060,779 | 2.7% | ||

| piotrgrafik | 0 | 52,604,431,032 | 7.92% | ||

| terrylovejoy | 0 | 2,112,700,720 | 12% | ||

| neneandy | 0 | 3,069,493,825 | 2.7% | ||

| pab.ink | 0 | 17,333,852,686 | 15% | ||

| goldrooster | 0 | 3,927,476,174 | 1.35% | ||

| soufiani | 0 | 2,149,748,060 | 1.08% | ||

| sportscontest | 0 | 2,495,061,644 | 2.7% | ||

| yrmaleza | 0 | 5,074,157,951 | 50% | ||

| stemng | 0 | 18,810,488,177 | 100% | ||

| kingabesh | 0 | 1,939,472,203 | 50% | ||

| miguelangel2801 | 0 | 764,641,165 | 50% | ||

| didic | 0 | 1,180,199,335 | 1.35% | ||

| unconditionalove | 0 | 573,233,455 | 4% | ||

| emiliomoron | 0 | 37,039,884,570 | 50% | ||

| beverages | 0 | 2,486,856,300 | 1.35% | ||

| dexterdev | 0 | 1,041,922,579 | 15% | ||

| verhp11 | 0 | 1,031,499,383 | 1% | ||

| photohunt | 0 | 2,523,838,324 | 2.7% | ||

| pkocjan | 0 | 4,164,615,071 | 6.4% | ||

| geopolis | 0 | 1,933,369,500 | 30% | ||

| robertbira | 0 | 3,206,381,323 | 7.5% | ||

| the.chiomz | 0 | 1,085,001,721 | 55% | ||

| alexdory | 0 | 36,828,603,659 | 30% | ||

| flugschwein | 0 | 891,870,765 | 25.5% | ||

| bertrayo | 0 | 727,129,085 | 1.35% | ||

| citimillz | 0 | 2,112,546,985 | 1.35% | ||

| movement19 | 0 | 5,036,781,512 | 2% | ||

| ladysalsa | 0 | 1,514,087,109 | 8% | ||

| doikao | 0 | 14,671,144,198 | 2.7% | ||

| francostem | 0 | 4,057,614,762 | 30% | ||

| kitalee | 0 | 445,015,143 | 1.35% | ||

| endopediatria | 0 | 684,961,822 | 20% | ||

| vicesrus | 0 | 1,848,009,589 | 1.35% | ||

| croctopus | 0 | 1,414,886,858 | 100% | ||

| zipporah | 0 | 1,226,293,712 | 0.54% | ||

| idkpdx | 0 | 145,353,422 | 1.35% | ||

| superlotto | 0 | 4,535,165,754 | 2.7% | ||

| djoi | 0 | 4,926,036,284 | 50% | ||

| frassman | 0 | 807,104,664 | 5% | ||

| reazuliqbal | 0 | 35,564,561,124 | 8% | ||

| henlicps | 0 | 654,537,122 | 8% | ||

| miroslavrc | 0 | 613,205,099 | 0.67% | ||

| simplymike | 0 | 6,457,982,530 | 5.6% | ||

| bscrypto | 0 | 5,044,105,606 | 1.35% | ||

| scottcbusiness | 0 | 1,161,636,273 | 1.35% | ||

| tomastonyperez | 0 | 16,465,290,732 | 50% | ||

| marcus0alameda | 0 | 900,285,371 | 50% | ||

| bil.prag | 0 | 636,908,374 | 0.13% | ||

| elvigia | 0 | 10,719,500,401 | 50% | ||

| bestboom | 0 | 2,039,650,887 | 8% | ||

| vittoriozuccala | 0 | 719,589,274 | 1.35% | ||

| sereze | 0 | 682,927,625 | 1.35% | ||

| qberry | 0 | 1,477,834,664 | 1.35% | ||

| lesmouths-travel | 0 | 2,340,977,284 | 30% | ||

| rambutan.art | 0 | 1,092,385,160 | 2.7% | ||

| braaiboy | 0 | 4,593,198,066 | 2.02% | ||

| freddio | 0 | 25,042,401,798 | 8% | ||

| blainjones | 0 | 21,873,974,937 | 14% | ||

| gadrian | 0 | 38,780,578,238 | 24% | ||

| cryptocoinkb | 0 | 3,447,330,311 | 1.35% | ||

| de-stem | 0 | 17,671,442,690 | 29.7% | ||

| serylt | 0 | 1,327,608,453 | 29.4% | ||

| laloretoyya | 0 | 1,798,735,798 | 8% | ||

| josedelacruz | 0 | 8,950,472,501 | 50% | ||

| kgakakillerg | 0 | 33,521,022,899 | 10% | ||

| andrewharland | 0 | 1,211,350,158 | 2.7% | ||

| mariusfebruary | 0 | 1,278,605,613 | 1.08% | ||

| we-are | 0 | 2,089,088,774 | 11.8% | ||

| indigoocean | 0 | 2,041,464,572 | 1.35% | ||

| incubot | 0 | 2,807,017,469 | 2.02% | ||

| deholt | 0 | 1,693,306,682 | 25.5% | ||

| steem.services | 0 | 10,102,983,120 | 2% | ||

| adrianhadjii | 0 | 4,106,329,358 | 2.7% | ||

| gwilberiol | 0 | 4,420,105,275 | 2.43% | ||

| netzisde | 0 | 3,549,108,333 | 2.7% | ||

| pladozero | 0 | 27,421,950,144 | 10% | ||

| nateaguila | 0 | 317,503,970,355 | 8% | ||

| stevenwood | 0 | 1,749,368,090 | 0.89% | ||

| temitayo-pelumi | 0 | 3,930,764,698 | 50% | ||

| andrick | 0 | 831,497,518 | 50% | ||

| yusvelasquez | 0 | 20,117,544,664 | 50% | ||

| doctor-cog-diss | 0 | 941,808,959 | 30% | ||

| trisolaran | 0 | 707,569,379 | 1.35% | ||

| thefoundation | 0 | 21,484,663,170 | 53.1% | ||

| musicvoter2 | 0 | 3,315,254,403 | 1% | ||

| marcuz | 0 | 1,071,152,755 | 15% | ||

| acont | 0 | 56,236,819,991 | 75% | ||

| uche-nna | 0 | 2,546,352,595 | 2.16% | ||

| schroders | 0 | 989,623,632 | 0.81% | ||

| anaestrada12 | 0 | 4,708,173,058 | 100% | ||

| citizendog | 0 | 3,364,516,582 | 2.7% | ||

| swisswitness | 0 | 5,188,207,639 | 8% | ||

| we-are-lucky | 0 | 13,162,381,607 | 44.5% | ||

| cheese4ead | 0 | 1,540,485,994 | 1.35% | ||

| blewitt | 0 | 3,063,226,485 | 0.13% | ||

| drsensor | 0 | 623,799,147 | 24% | ||

| olumzy | 0 | 2,923,419,335 | 0.81% | ||

| urdreamscometrue | 0 | 6,752,516,558 | 100% | ||

| juanmolina | 0 | 151,487,753,809 | 100% | ||

| bflanagin | 0 | 2,561,314,825 | 1.35% | ||

| astrophoto.kevin | 0 | 1,857,092,093 | 15% | ||

| armandosodano | 0 | 7,902,520,996 | 1.35% | ||

| dalz | 0 | 27,400,589,757 | 4% | ||

| goblinknackers | 0 | 106,041,913,293 | 4% | ||

| anttn | 0 | 7,356,127,107 | 30% | ||

| luppers | 0 | 3,082,025,530 | 4% | ||

| dlike | 0 | 57,842,343,797 | 8% | ||

| mobi72 | 0 | 592,899,080 | 1.35% | ||

| fran.frey | 0 | 4,052,214,002 | 50% | ||

| ummar | 0 | 3,719,125,882 | 15% | ||

| perpetuum-lynx | 0 | 865,037,482 | 29.4% | ||

| thurllanie | 0 | 642,124,012 | 50% | ||

| engrave | 0 | 173,417,182,731 | 7.2% | ||

| bobby.madagascar | 0 | 617,904,734 | 2% | ||

| stem-espanol | 0 | 71,147,023,640 | 100% | ||

| voter001 | 0 | 21,465,325,051 | 26.8% | ||

| voter002 | 0 | 2,642,297,375 | 13.4% | ||

| voter003 | 0 | 21,361,573,344 | 10.6% | ||

| voter000 | 0 | 2,069,345,785 | 5.7% | ||

| the.success.club | 0 | 1,167,752,122 | 1.35% | ||

| teemike | 0 | 799,135,532 | 50% | ||

| ldp | 0 | 880,416,349 | 8% | ||

| besheda | 0 | 1,383,885,772 | 30% | ||

| janettyanez | 0 | 81,939,845,923 | 50% | ||

| brianoflondon | 0 | 4,076,476,678 | 0.4% | ||

| giulyfarci52 | 0 | 1,655,488,052 | 50% | ||

| followjohngalt | 0 | 25,742,016,684 | 7.2% | ||

| steemcryptosicko | 0 | 6,065,608,784 | 0.54% | ||

| cakemonster | 0 | 4,557,479,256 | 4% | ||

| cowpatty | 0 | 571,118,843 | 15% | ||

| stem.witness | 0 | 112,870,929,729 | 30% | ||

| robmojo | 0 | 7,324,204,607 | 3% | ||

| wilmer14molina | 0 | 2,901,695,894 | 50% | ||

| bit4bit | 0 | 913,297,555 | 2.7% | ||

| samsemilia7 | 0 | 7,973,526,233 | 39% | ||

| steemstorage | 0 | 4,268,902,024 | 2.7% | ||

| navyactifit | 0 | 865,299,275 | 1.08% | ||

| permaculturedude | 0 | 3,245,918,539 | 8% | ||

| crowdwitness | 0 | 7,713,863,438 | 15% | ||

| ctime | 0 | 109,062,967,338 | 1% | ||

| hairgistix | 0 | 1,341,346,034 | 1.35% | ||

| goodcontentbot | 0 | 807,249,836 | 15% | ||

| haikusailor | 0 | 709,442,085 | 8% | ||

| abbenay | 0 | 647,058,098 | 4% | ||

| steemean | 0 | 9,987,992,929 | 5% | ||

| thelogicaldude | 0 | 13,647,021,045 | 10% | ||

| newton666 | 0 | 956,166,958 | 15% | ||

| lefty619 | 0 | 1,346,439,227 | 2.7% | ||

| filosof103 | 0 | 877,837,526 | 1.35% | ||

| mfblack | 0 | 3,885,027,283 | 7.6% | ||

| elements5 | 0 | 782,811,990 | 1.35% | ||

| photographercr | 0 | 601,039,605 | 0.67% | ||

| epicdice | 0 | 1,215,091,541 | 1.2% | ||

| trxjjbtc | 0 | 649,186,009 | 8% | ||

| game.player | 0 | 3,214,799,678 | 100% | ||

| deeanndmathews | 0 | 726,092,977 | 1.35% | ||

| scholaris | 0 | 39,625,917,921 | 7.5% | ||

| miniteut | 0 | 548,316,320 | 15% | ||

| threejay | 0 | 2,168,082,265 | 4% | ||

| yourfuture | 0 | 1,164,696,562 | 21% | ||

| fractalfrank | 0 | 1,699,471,453 | 1.35% | ||

| tinyhousecryptos | 0 | 518,461,076 | 5% | ||

| walterprofe | 0 | 59,671,034,919 | 100% | ||

| zeruxanime | 0 | 21,862,659,695 | 100% | ||

| afarina46 | 0 | 798,259,310 | 15% | ||

| titan-c | 0 | 678,792,223 | 2.7% | ||

| steemindian | 0 | 602,146,802 | 4% | ||

| shimozurdo | 0 | 601,336,577 | 8% | ||

| kgswallet | 0 | 543,981,949 | 20% | ||

| milu-the-dog | 0 | 3,953,866,990 | 8% | ||

| triplea.bot | 0 | 2,264,239,900 | 8% | ||

| steem.leo | 0 | 77,685,293,980 | 8% | ||

| onecent | 0 | 676,910,177 | 100% | ||

| liambu | 0 | 989,699,080 | 15% | ||

| elgranpoeta | 0 | 4,336,001,363 | 8% | ||

| asteroids | 0 | 824,747,474 | 7.2% | ||

| helengutier2 | 0 | 5,595,185,906 | 8% | ||

| ltzombie | 0 | 526,813,392 | 100% | ||

| tokensink | 0 | 1,223,235,092 | 2.7% | ||

| botante | 0 | 2,351,869,949 | 1% | ||

| elianaicgomes | 0 | 9,751,260,164 | 14% | ||

| maxuvd | 0 | 37,134,183,365 | 8% | ||

| mister.reatard | 0 | 6,394,749,151 | 50% | ||

| askari.ccc | 0 | 77,594,225 | 8.1% | ||

| joshmania | 0 | 115,809,444,220 | 7.5% | ||

| steemstem-trig | 0 | 2,284,120,745 | 30% | ||

| zyzzyva | 0 | 664,459,987 | 2.7% | ||

| tonimontana.neo | 0 | 0 | 0.51% | ||

| herzinfuck | 0 | 835,124,651 | 1.35% | ||

| therealyme | 0 | 321,228,495,190 | 5% | ||

| gerbo | 0 | 51,703,297 | 8% | ||

| delilhavores | 0 | 1,174,263,940 | 3% | ||

| roamingsparrow | 0 | 1,021,201,220 | 1.35% | ||

| toni.ccc | 0 | 38,680,696 | 1.9% | ||

| ribary | 0 | 2,703,557,375 | 4% | ||

| steemlatintrail | 0 | 1,833,573,830 | 100% | ||

| toni.pal | 0 | 0 | 1.43% | ||

| apx | 0 | 19,632,796 | 5% | ||

| gloriaolar | 0 | 1,132,375,994 | 0.81% | ||

| im-ridd | 0 | 559,161,831 | 1.35% | ||

| chireerocks.stem | 0 | 134,906,393 | 100% | ||

| disagio.gang | 0 | 596,814,182 | 2.7% | ||

| mice-k | 0 | 30,833,740,972 | 8% | ||

| troll3838 | 0 | 700,413,036 | 8% | ||

| dpend.active | 0 | 1,556,255,943 | 1.6% | ||

| andreina57 | 0 | 579,898,349 | 15% | ||

| fsm-core | 0 | 9,869,909,727 | 50% | ||

| hornetsnest | 0 | 2,036,984,998 | 1.35% | ||

| stemsocial | 0 | 12,190,889,512 | 30% | ||

| hive.consultant | 0 | 873,330,921 | 2.16% | ||

| polish.hive | 0 | 116,227,790,588 | 8% | ||

| kodeblaccc | 0 | 853,747,878 | 1.35% | ||

| monster-burner | 0 | 619,234,242 | 4% | ||

| dcityrewards | 0 | 461,055,725,141 | 8% | ||

| hiveonboard | 0 | 7,350,121,302 | 3% | ||

| hivelist | 0 | 1,964,693,783 | 0.8% | ||

| shinyrygaming | 0 | 1,359,535,645 | 15% | ||

| hive-101493 | 0 | 1,096,472,698 | 15% | ||

| poshbot | 0 | 5,001,671,182 | 8% | ||

| hivecur | 0 | 16,333,372,591 | 8% | ||

| asa-raw | 0 | 966,426,545,770 | 25% | ||

| quinnertronics | 0 | 3,653,865,164 | 2% | ||

| malenavargas | 0 | 5,880,186,215 | 100% | ||

| recoveryinc | 0 | 2,192,994,606 | 4% | ||

| sevenoh-fiveoh | 0 | 601,398,209 | 5% | ||

| coffeebender | 0 | 518,082,211 | 25% | ||

| death-and-taxes | 0 | 3,818,541,141 | 50% | ||

| chin-diapers | 0 | 1,305,769,147 | 2.7% | ||

| stemcur | 0 | 828,792,830 | 100% | ||

| stemline | 0 | 11,013,490,463 | 100% | ||

| hivechat | 0 | 956,491,660 | 4% | ||

| sillybilly | 0 | 740,476 | 30% | ||

| he-index | 0 | 9,561,054,895 | 20% | ||

| ctpsb.stem | 0 | 715,942,852 | 100% | ||

| arnol99 | 0 | 2,191,773,937 | 100% | ||

| ctpsb.cut | 0 | 699,627,898 | 20% | ||

| samrisso | 0 | 104,699,683,388 | 4% | ||

| hypnochain | 0 | 0 | 2.7% | ||

| eturnerx-dbuzz | 0 | 21,516,437,617 | 53.9% | ||

| cbridges573 | 0 | 922,537,591 | 5% | ||

| ima-stoner | 0 | 904,299,686 | 1.35% | ||

| eturnerx-honey | 0 | 2,072,811,052 | 5.6% | ||

| radiofreefutura | 0 | 528,702,655 | 1.35% |

https://twitter.com/CARLOSJB84/status/1377613194261360641

| author | poshbot |

|---|---|

| permlink | re-problems-in-the-drilling-of-oil-wells-20210401t132601z |

| category | hive-196387 |

| json_metadata | "{"app": "beem/0.24.20"}" |

| created | 2021-04-01 13:26:00 |

| last_update | 2021-04-01 13:26:00 |

| depth | 1 |

| children | 0 |

| last_payout | 2021-04-08 13:26:00 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 0.000 HBD |

| curator_payout_value | 0.000 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 57 |

| author_reputation | 5,554,335,374,496 |

| root_title | "Problems in the drilling of oil wells" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 102,745,889 |

| net_rshares | 0 |

<div class='text-justify'> <div class='pull-left'> <img src='https://stem.openhive.network/images/stemsocialsupport7.png'> </div> Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us! Please consider <a href="https://hivesigner.com/sign/update-proposal-votes?proposal_ids=%5B91%5D&approve=true">supporting our funding proposal</a>, <a href="https://hivesigner.com/sign/account_witness_vote?approve=1&witness=stem.witness">approving our witness</a> (@stem.witness) or delegating to the @stemsocial account (for some ROI). Please consider using the <a href='https://stem.openhive.network'>STEMsocial app</a> app and including @stemsocial as a beneficiary to get a stronger support. <br /> <br />

| author | steemstem |

|---|---|

| permlink | re-carlos84-problems-in-the-drilling-of-oil-wells-20210402t000616980z |

| category | hive-196387 |

| json_metadata | {"app":"stemsocial"} |

| created | 2021-04-02 00:06:18 |

| last_update | 2021-04-02 00:06:18 |

| depth | 1 |

| children | 0 |

| last_payout | 2021-04-09 00:06:18 |

| cashout_time | 1969-12-31 23:59:59 |

| total_payout_value | 0.000 HBD |

| curator_payout_value | 0.000 HBD |

| pending_payout_value | 0.000 HBD |

| promoted | 0.000 HBD |

| body_length | 778 |

| author_reputation | 262,017,435,115,313 |

| root_title | "Problems in the drilling of oil wells" |

| beneficiaries | [] |

| max_accepted_payout | 1,000,000.000 HBD |

| percent_hbd | 10,000 |

| post_id | 102,757,409 |

| net_rshares | 0 |

hiveblocks

hiveblocks